Kwinqanaba loshishino lwemveliso yanamhlanje, izixhobo zoomatshini be-CNC ziye zaba ngumqolo wemveliso kunye nezakhono zabo ezisebenzayo nezichanekileyo. Iimfuno zokuchaneka komatshini kwiindawo eziphambili zezixhobo zoomatshini be-CNC ngokungathandabuzekiyo zizinto eziphambili ezimisela ukhetho lwenqanaba lokuchaneka izixhobo zomatshini we-CNC.

Izixhobo zoomatshini be-CNC zihlelwa ngokweendidi ezahlukeneyo ezifana nokulula, ukusebenza ngokupheleleyo, kunye nokuchaneka kwe-ultra ngenxa yokusetyenziswa kwazo okwahlukeneyo, kwaye amanqanaba abo okuchaneka ahluka kakhulu. Izixhobo zomatshini ezilula ze-CNC zisahlala kwindawo yangoku yeelathe kunye noomatshini bokugaya, kunye nesisombululo esincinci se-0.01mm, kunye nokunyakaza kunye nokuchaneka komatshini ngokubanzi ukusuka kwi-0.03 ukuya kwi-0.05 mm okanye ngaphezulu. Nangona ukuchaneka kulinganiselwe, kwezinye iimeko zomatshini apho iimfuno ezichanekileyo zingekho ngqongqo kakhulu, izixhobo ezilula zoomatshini be-CNC zidlala indima engenakuthathelwa indawo ngenxa yeenzuzo zabo zoqoqosho kunye nokusebenza lula.

Ngokwahlukileyo, izixhobo zomatshini ze-CNC ezichanekileyo ze-Ultra zenzelwe ngokukodwa iimfuno ezikhethekileyo zomatshini, ngokuchaneka okumangalisayo kwe-0.001mm okanye ngaphantsi. Ukuchaneka kwe-Ultra CNC izixhobo zoomatshini zihlala zisetyenziselwa ukuchaneka okuphezulu kunye neendawo ezinqamlezileyo ezifana ne-aerospace kunye nezixhobo zonyango, ukubonelela ngenkxaso yobugcisa obuqinileyo bokwenza izinto ezinzima kakhulu kunye nezifuna ukuchaneka.

Ngokombono wokuchaneka, izixhobo zoomatshini be-CNC zinokuphinda zohlulwe zibe ziindidi eziqhelekileyo nezichanekileyo. Ngokuqhelekileyo, kukho izinto zokuhlola ukuchaneka kwe-20 ukuya kwi-30 yezixhobo zoomatshini be-CNC, kodwa ezona zibalulekileyo kunye nabameli kukuchaneka kokubeka indawo ye-axis enye, i-axis enye ephindaphindiweyo yokuchaneka kokumisa, kunye nokujikeleza kweqhekeza lovavanyo oluveliswa ngamazembe amabini okanye ngaphezulu adibeneyo.

Ukuchaneka kokubeka kunye nokuphindaphinda ukuchaneka kokumisa kuyancedisana kunye kunye kunye nokuchaza iphrofayili echanekileyo ebanzi yamacandelo ahambayo e-axis yesixhobo somatshini. Ngokukodwa ngokuphindaphindiweyo kokuchaneka kokumisa ngokuphindaphindiweyo, kufana nesibuko, sibonisa ngokucacileyo ukuzinza kwe-axis kuyo nayiphi na indawo yokumisa ngaphakathi kwe-stroke yayo. Olu phawu luba sisiseko sokulinganisa ukuba i-shaft inokusebenza ngokuzinzileyo nangokuthembekileyo, kwaye ibalulekile ekuqinisekiseni ukusebenza okuzinzile kwexesha elide kwesixhobo somatshini kunye nokuhambelana komgangatho womatshini.

I-software yenkqubo ye-CNC yanamhlanje ifana nengcibi ehlakaniphile, enemisebenzi yembuyekezo ecebileyo kunye neyohlukeneyo, ekwazi ukubuyisela ngobuchule iimpazamo zenkqubo eziveliswe kwikhonkco ngalinye lekhonkco lokuthumela ukutya ngokuchanekileyo nangokuzinzileyo. Ukuthatha amakhonkco ahlukeneyo ekhonkco lokuhambisa njengomzekelo, utshintsho kwizinto ezifana nokucocwa, ukuguqulwa kwe-elastic, kunye nokuqina koqhagamshelwano akutshintshi rhoqo, kodwa kubonisa utshintsho oluguquguqukayo oluguquguqukayo oluguquguqukayo kunye nezinto eziguquguqukayo ezifana nobukhulu bomthwalo we-workbench, ubude bomgama wokuhamba, kunye nesantya sokumisa ukuhamba.

Kwezinye iisistim ezivulekileyo ze-loop kunye ne-semi-loop-loop feed servo, amacandelo okuqhuba oomatshini emva kwezixhobo zokulinganisa zifana neenqanawa ezihamba phambili emoyeni nasemvuleni, ngokuxhomekeke kwiimeko ezahlukeneyo zengozi. Umzekelo, isenzeko sokwandiswa kwe-thermal yezikrufu zebhola kunokubangela ukukhukuliseka kwindawo eyiyo yokuma yebhentshi yokusebenzela, ngaloo ndlela kuzisa iimpazamo ezibalulekileyo ezingahleliweyo ekuchanekeni komatshini. Isishwankathelo, ukuba kukho ukhetho olufanelekileyo kwinkqubo yokhetho, akukho mathandabuzo ukuba izixhobo ezinomgangatho ophezulu kakhulu wokuphindaphinda ukuchaneka kufuneka zibekwe phambili, zongeza i-inshurensi eyomeleleyo kumgangatho wokucubungula.

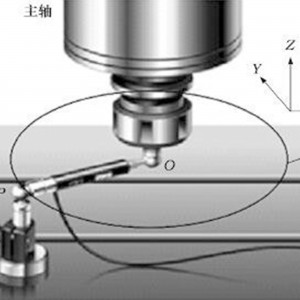

Ukuchaneka komphezulu we-cylindrical wokusila okanye i-grooves ye-spiral spiral (imisonto), njengerula elungileyo yokulinganisa ukusebenza kwesixhobo somatshini, sisalathiso esingundoqo sokuvavanya ngokubanzi i-servo ilandelayo iimpawu zentshukumo ye-axis ye-CNC (ii-axes ezimbini okanye ezintathu) kunye nomsebenzi wokudibanisa wenkqubo yomatshini we-CNC. Indlela esebenzayo yokumisela esi salathisi kukulinganisa ukujikeleza kwe-cylindrical surface esetyenzisiweyo.

Kwinkqubo yokusika iziqwenga zovavanyo kwizixhobo zomatshini we-CNC, indlela yokusila i-oblique yesikwere emacala amane ibonisa ixabiso layo elilodwa, elinokugweba ngokuchanekileyo ukuchaneka kokusebenza kweezembe ezimbini ezilawulwayo kwi-linear interpolation motion. Xa usenza lo msebenzi wokusika ulingo, kuyimfuneko ukufakela ngononophelo isiphelo sokusila esisetyenziselwa ukuchaneka komatshini kwi-spindle yomatshini, kwaye emva koko wenze ukugaya ngokucokisekileyo kwisampulu yesetyhula ebekwe kwibhentshi yokusebenza. Kwizixhobo zomatshini ezincinci kunye nobukhulu obuphakathi, ubukhulu bomzekelo wesetyhula ngokuqhelekileyo bukhethwa phakathi kwe-¥ 200 kunye ne-¥ 300. Olu luhlu luye lwavavanywa ekusebenzeni kwaye lunokuvavanya ngokufanelekileyo ukuchaneka komatshini wesixhobo somatshini.

Emva kokugqiba ukugaya, beka ngokucophelela i-specimen esikiweyo kwimitha ejikelezayo kwaye ulinganise ukujikeleza kwendawo yayo eyenziwe ngomatshini usebenzisa isixhobo esichanekileyo sokulinganisa. Kule nkqubo, kuyimfuneko ukujonga kunye nokuhlalutya iziphumo zomlinganiselo ngovakalelo. Ukuba kukho iipateni zokungcangcazela zemilling cutter ezicacileyo kumphezulu we-cylindrical osiliweyo, iyasilumkisa ukuba isantya sokudibanisa isixhobo somatshini sinokungazinzi; Ukuba ukujikeleza okuveliswe ngokusila kubonisa iimpazamo ezicacileyo ze-elliptical, ngokuqhelekileyo kubonisa ukuba iinzuzo zeendlela ezimbini ezilawulwayo ze-axis kwi-interpolation motion azizange zihambelane kakuhle; Xa kukho amanqaku okumisa kwindawo nganye elawulwayo yokutshintsha intshukumo ye-axis intshukumo yokutshintsha kumphezulu ojikelezayo (oko kukuthi, kwintshukumo eqhubekayo yokusika, ukumisa isindululo sokutya kwindawo ethile kuya kwenza icandelo elincinci leempawu zokusika isinyithi kumphezulu womatshini), oku kuthetha ukuba ukucocwa phambili kunye nokubuyela umva kwe-axis akuzange kulungiswe kwimeko efanelekileyo.

Ingqikelelo yokuchaneka kokuma kwe-axis enye ibhekisa kuluhlu lwempazamo olwenziweyo xa ubeka nayiphi na indawo ngaphakathi kwe-axis stroke. Kufana nendlu yesibane, ekhanyisa ngokuthe ngqo ukuchaneka komatshini wesixhobo somatshini, kwaye ngokungathandabuzekiyo ibe sesinye sezona zalathisi zibalulekileyo zezixhobo zoomatshini beCNC.

Okwangoku, kukho iiyantlukwano ezithile kwimimiselo, iinkcazo, iindlela zokulinganisa, kunye neendlela zokucubungula idatha ye-axis enye yokumisa ukuchaneka phakathi kwamazwe kwihlabathi jikelele. Xa ukuqaliswa kweentlobo ngeentlobo zedatha yesampula yesixhobo somatshini we-CNC, imigangatho eqhelekileyo kwaye ikhankanywe ngokubanzi ibandakanya i-American Standard (NAS), imigangatho ecetyiswayo yi-American Machine Tool Manufacturers Association, i-German Standard (VDI), i-Japan Standard (JIS), i-International Organisation for Standardization (ISO), kunye ne-Chinese National Standard (GB).

Phakathi kwale migangatho imangalisayo, imigangatho yaseJapan ithambile ngokwemigaqo. Indlela yokulinganisa isekelwe kwiseti enye yedatha ezinzileyo, kwaye ngobuchule isebenzisa amaxabiso ± ukucinezela ixabiso lempazamo ngesiqingatha. Ngenxa yoko, ukuchaneka kokubeka okufunyenwe kusetyenziswa iindlela zomlinganiso oqhelekileyo waseJapan kuhlala kohluka ngokuphindwe kabini xa kuthelekiswa neminye imigangatho.

Nangona eminye imigangatho yahlukile kwindlela abaqhuba ngayo idatha, imiliselwe ngokunzulu kumhlaba wezibalo zempazamo ukuhlalutya kunye nokulinganisa ukuchaneka kwendawo. Ngokukodwa, kwimpazamo ethile yokubeka indawo kwi-axis stroke elawulwayo yesixhobo somatshini we-CNC, kufuneka ikwazi ukubonakalisa iimpazamo ezinokuthi zenzeke ngexesha lamawaka amaxesha okumisa ngexesha lokusetyenziswa kwexesha elide lesixhobo somatshini kwixesha elizayo. Nangona kunjalo, umda ngokweemeko zokwenyani, sihlala singenza kuphela inani eliqingqiweyo lemisebenzi ngexesha lokulinganisa, ngokuqhelekileyo amaxesha ama-5 ukuya ku-7.

Ukuchaneka komgwebo wezixhobo zoomatshini be-CNC kufana nohambo olucelomngeni lokusombulula iipuzzle, aluphunyezwanga ngobusuku. Ezinye izikhombisi zokuchaneka zifuna ukuhlolwa ngononophelo kunye nohlalutyo lweemveliso ezicwangcisiweyo emva kokusebenza kwangempela komatshini wesixhobo somatshini, ngokungathandabuzekiyo kwandisa ubunzima kunye nobunzima bokugweba ngokuchanekileyo.

Ukuze kuqinisekiswe ukukhethwa kwezixhobo zomatshini ze-CNC ezihlangabezana neemfuno zokuvelisa, kufuneka sihlolisise ngokunzulu iiparitha zokuchaneka kwezixhobo zoomatshini kwaye siqhube uhlalutyo olubanzi kunye neenkcukacha ngaphambi kokwenza izigqibo zokuthenga. Kwangaxeshanye, kubalulekile ukuba nonxibelelwano olwaneleyo nolunzulu kunye notshintshiselwano kunye nabavelisi bezixhobo zoomatshini be-CNC. Ukuqonda inqanaba lenkqubo yemveliso yomenzi, ukungqongqo kwamanyathelo olawulo lomgangatho, kunye nokugqibelela kwenkonzo emva kokuthengisa kunokubonelela ngesiseko esibaluleke ngakumbi sesalathiso sokwenza kwethu izigqibo.

Kwiimeko zesicelo esisebenzayo, uhlobo kunye nenqanaba lokuchaneka kwezixhobo zoomatshini be-CNC kufuneka kwakhona zikhethwe ngokwesayensi nangengqiqo ngokusekelwe kwimisebenzi ethile yomatshini kunye neemfuno ezichanekileyo zamacandelo. Kwiindawo ezineemfuno ezichaneke kakhulu, izixhobo zoomatshini ezixhotyiswe ngeenkqubo eziphambili ze-CNC kunye namacandelo achanekileyo aphezulu kufuneka ziqwalaselwe kuqala ngaphandle kokuthandabuza. Olu khetho aluqinisekisi kuphela umgangatho ogqwesileyo wokucubungula, kodwa luphucula ukusebenza kakuhle kwemveliso, ukunciphisa amaxabiso okulahlwa, kwaye kuzisa inzuzo ephezulu yezoqoqosho kwishishini.

Ukongeza, uvavanyo oluchanekileyo oluchanekileyo kunye nokugcinwa ngokucokisekileyo kwezixhobo zoomatshini be-CNC ngamanyathelo aphambili okuqinisekisa ukusebenza okuzinzile kwexesha elide kunye nokugcina amandla omatshini aphezulu. Ngokuchonga ngokukhawuleza kunye nokusombulula imiba enokubakho yokuchaneka, ubomi benkonzo yezixhobo zoomatshini bunokwandiswa ngokufanelekileyo, ukuqinisekisa ukuzinza nokuthembeka komgangatho womatshini. Kanye njengokukhathalela imoto yomdyarho exabisekileyo, ingqwalasela eqhubekayo kuphela kunye nokugcinwa kwayo kunokuyigcina iqhuba kakuhle emgceni.

Isishwankathelo, ukuchaneka kwezixhobo zoomatshini be-CNC yinkcazo yokuqwalasela ebanzi kunye nebanzi, ehamba kuyo yonke inkqubo yoyilo lomatshini kunye nophuhliso, ukuvelisa kunye nokudibanisa, ukufakela kunye nokuchithwa, kunye nokusetyenziswa kunye nokugcinwa kwansuku zonke. Kuphela ngokuqonda ngokubanzi kunye nokulawula ulwazi olufanelekileyo kunye neteknoloji sinokuthi sikhethe ngobulumko esona sixhobo somatshini we-CNC kwimisetyenzana yokwenyani yemveliso, sicofe ngokupheleleyo ekusebenzeni kwayo okunokwenzeka, kunye nokufaka amandla awomeleleyo kunye nenkxaso kuphuhliso olomeleleyo lweshishini lemveliso.