Inkqubo ye-CNC yezixhobo zomshini we-CNC ziquka izixhobo ze-CNC, i-feed drive (iyunithi yokulawula isantya sokutya kunye ne-servo motor), i-spindle drive (iyunithi yokulawula i-spindle kunye ne-spindle motor) kunye namacandelo okufumanisa. Lo mxholo ungentla kufuneka ubandakanywe xa ukhetha inkqubo yolawulo lwamanani. 1. Ukukhethwa kwesixhobo se-CNC (1) Uhlobo lokukhetha Khetha isixhobo esihambelanayo se-CNC ngokohlobo lwesixhobo somatshini we-CNC. Ngokuqhelekileyo, isixhobo se-CNC sineentlobo zokucubungula ezifanelekileyo kwimoto, ukubhola, ukudika, ukugaya, ukugaya, ukunyathela, ukusika i-spark yombane, njl., kwaye kufuneka kukhethwe ngendlela ejoliswe kuyo. ( 2) Ukukhethwa kokusebenza kwezixhobo ezahlukeneyo zokulawula amanani kuyahluka kakhulu. Inani lee-axis zokulawula igalelo li-single-axis, i-2-axis, i-3-axis, i-4-axis, i-5-axis, okanye nangaphezulu kwe-10, ngaphezu kwe-20; inani lamazembe oqhagamshelwano yi-2 okanye ngaphezulu kwe-3 yezembe, kwaye isantya esiphezulu sokutya yi-10m/min, 15m/min, 24m/mi N,240m/min; isisombululo 0.01mm, 0.001mm, 0.0001mm. Ezi zalathi zihlukile, kwaye ixabiso likwahlukile. Kufuneka isekelwe kwiimfuno zangempela zesixhobo somatshini. Ngokomzekelo, i-2-axis okanye i-4-axis (isixhobo esiphindwe kabini) ulawulo lukhethiwe ukwenzela ukuguqulwa ngokubanzi, kwaye ngaphezu kwe-3-axis ikhonkco ikhethiwe ukwenzela ukulungiswa kweendawo zendiza. Sukusukela inqanaba lamva nje neliphezulu, kuya kufuneka wenze ukhetho olufanelekileyo.

(3) Ukukhethwa komsebenzi Inkqubo ye-CNC yezixhobo zomshini we-CNC inemisebenzi emininzi, kubandakanywa nemisebenzi esisiseko - imisebenzi ebalulekileyo yezixhobo ze-CNC; imisebenzi yokukhetha - imisebenzi yabasebenzisi ukuba bayikhethe. Eminye yemisebenzi ikhethiweyo ukusombulula izinto ezahlukeneyo zokucwangcisa, ezinye ziphucula umgangatho wokulungiswa, ezinye ziququzelela inkqubo, kwaye ezinye ziphucula ukusebenza kunye nokugcinwa kokusebenza. Eminye imisebenzi yokhetho ifanelekile, kwaye kufuneka ukhethe omnye ukukhetha lo. Ngoko ke, kuyimfuneko ukukhetha ngokweemfuno zoyilo lwesixhobo somatshini, musa ukuhlalutya, khetha umsebenzi ngamanyathelo amaninzi, kwaye ushiye imisebenzi echaphazelekayo, ukwenzela ukunciphisa umsebenzi wesixhobo somatshini we-CNC kwaye kubangele ilahleko engeyomfuneko. Kukho iintlobo ezimbini zabalawuli abacwangcisekileyo kumsebenzi wokukhetha: eyakhelwe ngaphakathi kunye nokuzimela. Kungcono ukhethe imodeli eyakhelweyo, enemizekelo eyahlukeneyo. Okokuqala, kufuneka kukhethwe ngokwenani leegalelo kunye neempawu zemveliso phakathi kwesixhobo se-CNC kunye nesixhobo somatshini. Amanqaku akhethiweyo kufuneka abe ngamanqaku asebenzayo, kwaye ikomityi inokongeza kwaye itshintshe imfuno yokulawula ukusebenza. Okwesibini, kuyimfuneko ukuqikelela ubungakanani beprogram yokulandelelana kwaye ukhethe umthamo wokugcina. Umlinganiselo weprogram uyanda kunye nobunzima besixhobo somatshini, kwaye umthamo wokugcina uyanda. Kufuneka ikhethwe ngokufanelekileyo ngokwemeko ethile. Kukwakho ixesha lokucubungula, umsebenzi womyalelo, isibali-xesha, ikhawuntara, ireyiti yangaphakathi kunye nezinye iinkcukacha zobugcisa, kwaye ubungakanani kufuneka buhlangabezane neemfuno zoyilo.

(3) Ukukhethwa komsebenzi Inkqubo ye-CNC yezixhobo zomshini we-CNC inemisebenzi emininzi, kubandakanywa nemisebenzi esisiseko - imisebenzi ebalulekileyo yezixhobo ze-CNC; imisebenzi yokukhetha - imisebenzi yabasebenzisi ukuba bayikhethe. Eminye yemisebenzi ikhethiweyo ukusombulula izinto ezahlukeneyo zokucwangcisa, ezinye ziphucula umgangatho wokulungiswa, ezinye ziququzelela inkqubo, kwaye ezinye ziphucula ukusebenza kunye nokugcinwa kokusebenza. Eminye imisebenzi yokhetho ifanelekile, kwaye kufuneka ukhethe omnye ukukhetha lo. Ngoko ke, kuyimfuneko ukukhetha ngokweemfuno zoyilo lwesixhobo somatshini, musa ukuhlalutya, khetha umsebenzi ngamanyathelo amaninzi, kwaye ushiye imisebenzi echaphazelekayo, ukwenzela ukunciphisa umsebenzi wesixhobo somatshini we-CNC kwaye kubangele ilahleko engeyomfuneko. Kukho iintlobo ezimbini zabalawuli abacwangcisekileyo kumsebenzi wokukhetha: eyakhelwe ngaphakathi kunye nokuzimela. Kungcono ukhethe imodeli eyakhelweyo, enemizekelo eyahlukeneyo. Okokuqala, kufuneka kukhethwe ngokwenani leegalelo kunye neempawu zemveliso phakathi kwesixhobo se-CNC kunye nesixhobo somatshini. Amanqaku akhethiweyo kufuneka abe ngamanqaku asebenzayo, kwaye ikomityi inokongeza kwaye itshintshe imfuno yokulawula ukusebenza. Okwesibini, kuyimfuneko ukuqikelela ubungakanani beprogram yokulandelelana kwaye ukhethe umthamo wokugcina. Umlinganiselo weprogram uyanda kunye nobunzima besixhobo somatshini, kwaye umthamo wokugcina uyanda. Kufuneka ikhethwe ngokufanelekileyo ngokwemeko ethile. Kukwakho ixesha lokucubungula, umsebenzi womyalelo, isibali-xesha, ikhawuntara, ireyiti yangaphakathi kunye nezinye iinkcukacha zobugcisa, kwaye ubungakanani kufuneka buhlangabezane neemfuno zoyilo.

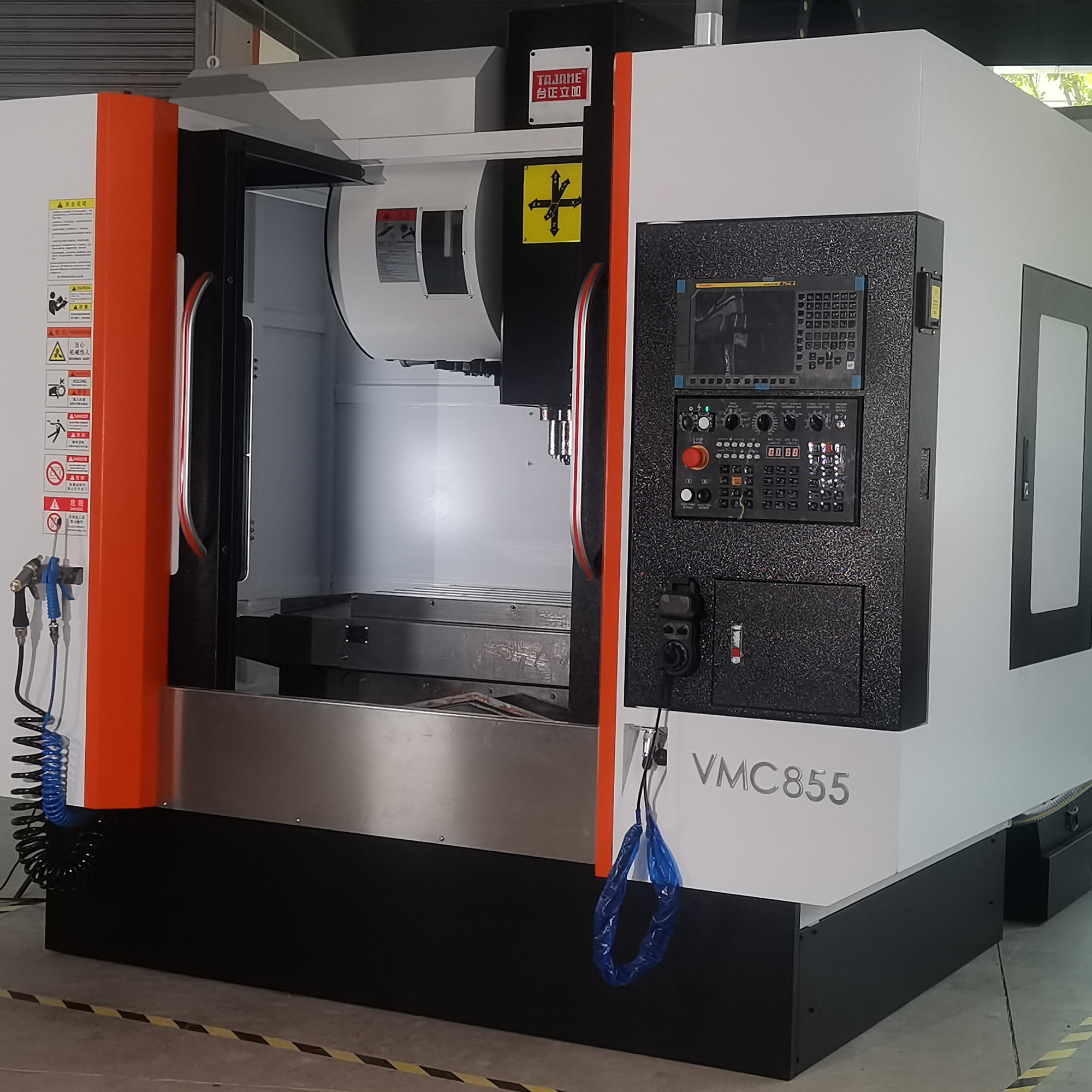

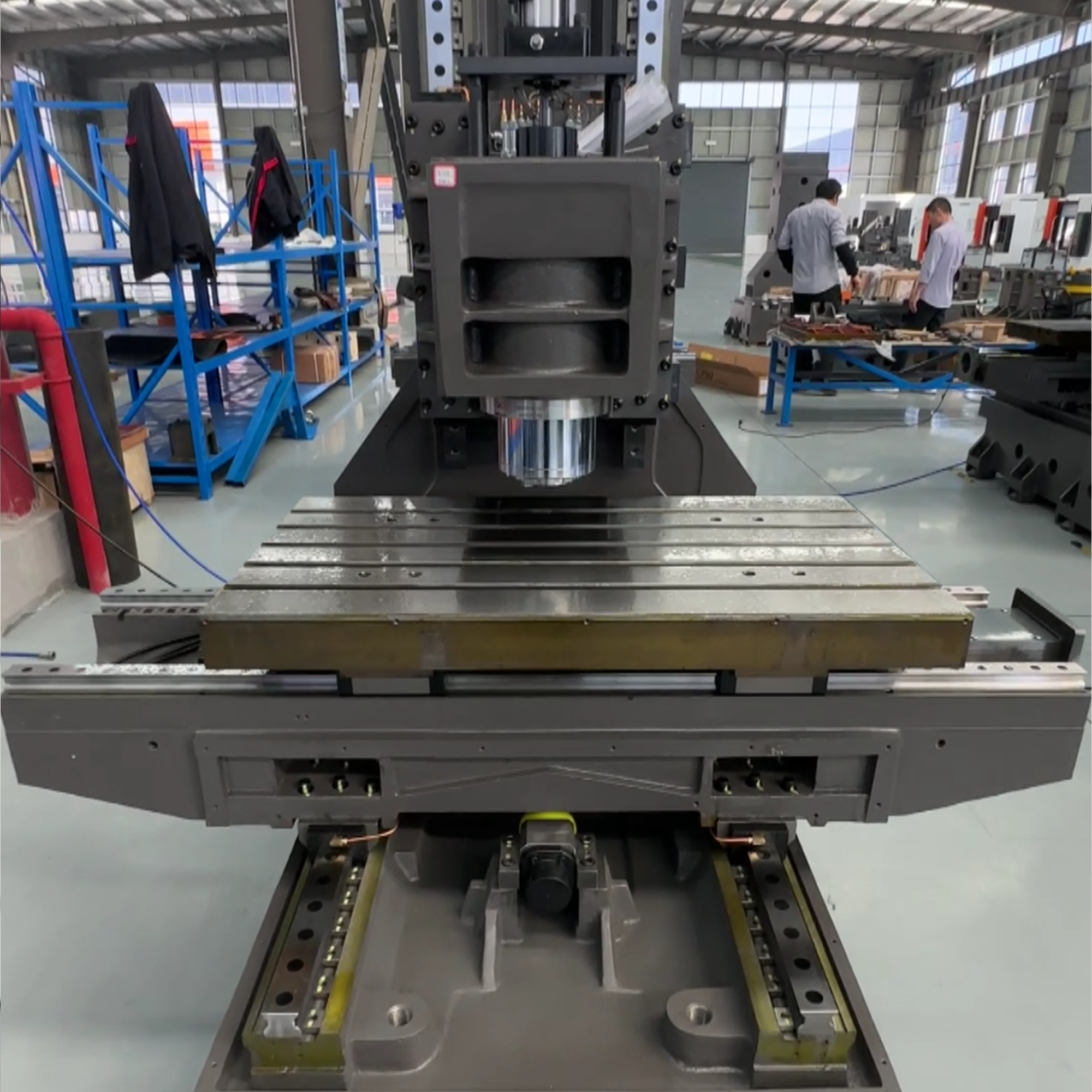

( 4 ) Ixabiso leXu Ze kumazwe ahlukeneyo kunye nabavelisi bezixhobo ze-CNC bavelisa iinkcukacha ezahlukeneyo zeemveliso ezinomahluko omkhulu kwixabiso. Ngesiseko sokwanelisa uhlobo lolawulo, ukusebenza kunye nokukhethwa komsebenzi, kufuneka sihlalutye ngokubanzi umlinganiselo wexabiso lentsebenzo kwaye sikhethe izixhobo ze-CNC ezinomlinganiselo ophezulu wokusebenza-xabiso ukwenzela ukunciphisa iindleko.(5) Xa ukhetha isixhobo solawulo lwamanani esihlangabezana neemfuno zobugcisa, ukukhethwa kweenkonzo zobugcisa kufuneka kuthathelwe ingqalelo isidima somenzi, ukuba imiyalelo yemveliso kunye namanye amaxwebhu anokugqitywa ngumsebenzi wokuqeqesha kunye nokuqeqesha abasebenzi. Ngaba kukho isebe elikhethekileyo lenkonzo yobugcisa ukuze libonelele ngeendawo ezisecaleni kunye neenkonzo zokugcinwa kwangexesha ixesha elide ukuze kuphunyezwe izibonelelo zobugcisa nezoqoqosho. 2. Ukukhethwa kwe-feed drive (1) i-AC servo motor ikhethwayo, kuba xa kuthelekiswa ne-DC motor, i-rotor inertia incinci, impendulo eguquguqukayo ilungile, amandla aphumayo makhulu, isantya sokujikeleza siphezulu, isakhiwo silula, ixabiso liphantsi, kwaye indawo yesicelo ayikhawulelwanga. ( 2) Khetha i-servo motor yenkcazo efanelekileyo ngokubala ngokuchanekileyo iimeko zomthwalo ezongeziweyo kwi-motor shaft. ( 3 ) Umvelisi we-feed drive unikezela uluhlu lweeseti ezipheleleyo zeemveliso zeyunithi yokulawula isantya sokutya kunye ne-servo motor, ngoko emva kokuba imoto ye-servo ikhethiwe, iyunithi yokulawula isantya ehambelanayo ikhethwa kwincwadana yemveliso. 3. Ukukhethwa kwe-spindle drive (1) I-motor spindle engundoqo ikhethwayo, kuba ayinayo imiqobo yokutshintsha, isantya esiphezulu kunye nomthamo omkhulu njenge-DC spindle motor. Uluhlu oluqhubekayo lolawulo lwesantya samandla lukhulu, ingxolo iphantsi, kwaye ixabiso liphantsi. Okwangoku, i-85% yezixhobo zomatshini ze-CNC ziqhutywa yi-AC spindles emhlabeni. ( Isixhobo somatshini we-CNC) (2) Khetha i-spindle motor ngokwemigaqo elandelayo: 1 Amandla okusika abalwa ngokwezixhobo zoomatshini ezahlukeneyo, kunye nemoto ekhethiweyo kufuneka ihlangabezane nale mfuneko; I-2 Ngokwexesha elifunekayo lokunyuka kwe-spindle kunye ne-deceleration, kubalwa ukuba amandla ombane akufanele adlule ubuninzi bamandla okukhutshwa kwemoto; 3 Xa i-spindle ifuneka ukuba iqale rhoqo kwaye ibhuleki, inqanaba kufuneka libalwe. Ixabiso le-avareji yamandla alinako ukudlula umlinganiselo oqhubekayo wokuphuma kwamandla emoto;④ Kwimeko apho umphezulu ongaguqukiyo ufuneka ukuba ulawulwe, isixa samandla okusika afunekayo kulawulo lwesantya esingaguqukiyo somphezulu kunye namandla afunekayo ukukhawulezisa aya kuba ngaphakathi kuluhlu lwamandla anokubonelela ngemoto. (3) Umenzi we-spindle drive ubonelela ngothotho lweeseti ezipheleleyo zeemveliso zeyunithi yokulawula isantya sokusonta kunye nemoto yokuphotha, ke emva kokuba i-spindle motor ikhethiwe, iyunithi yokulawula isantya sokusonta ehambelanayo ikhethwa kwincwadana yemveliso. ( 4 ) Xa i-spindle iyadingeka kulawulo lwe-directional, ngokwemeko yokwenyani yesixhobo somatshini, khetha i-encoder yendawo okanye i-sensor yamagnetic ukuqonda ulawulo lwe-spindle direction. 4. Ukukhethwa kwezinto zokubona (1) Ngokwesicwangciso solawulo lwendawo yesistim yokulawula amanani, ukufuduka komgca wesixhobo somatshini kulinganiswa ngokuthe ngqo okanye ngokungathanga ngqo, kwaye izinto zokukhangela umgca okanye i-rotary zikhethiwe. Okwangoku, ulawulo lwe-semi-closed-loop lusetyenziswa ngokubanzi kwizixhobo zomatshini we-CNC, kunye nezinto zokulinganisa i-angle ejikelezayo (i-rotary transformers, i-pulse encoders) ikhethiwe. (2) Ngokweemfuno zezixhobo zomatshini ze-CNC zokubona ukuchaneka okanye ukukhawuleza, khetha indawo okanye izinto zokukhangela isantya (i-generator yokuvavanya, i-pulse encoders). Ngokuqhelekileyo, izixhobo zoomatshini abakhulu zihlangabezana neemfuno zesantya, kunye nokuchaneka okuphezulu, izixhobo zoomatshini ezincinci kunye neziphakathi ubukhulu becala zihlangabezana nokuchaneka. Isisombululo sesiqalelo esikhethiweyo sobhaqo ngokuqhelekileyo lulandelelwano lobukhulu obuphezulu kunokulungiswa kokuchaneka. ( 3 ) Okwangoku, eyona nto isetyenziswa ngokuqhelekileyo isixhobo sokufumanisa izixhobo zomatshini we-CNC (i-horizontal boring kunye nomatshini wokugaya) yi-photoelectric pulse encoder, ekhetha i-pulse encoder yeenkcukacha ezihambelanayo ngokwe-ball screw pitch yesixhobo somatshini we-CNC, ukuhamba okuncinci kwenkqubo ye-CNC, ukukhuliswa komyalelo kunye nokwandiswa kokufumanisa. ( 4) Xa ukhetha into yokufumanisa, kufuneka kuthathelwe ingqalelo ukuba isixhobo sokulawula amanani sinesekhethi ye-interface ehambelanayo.

( 4 ) Ixabiso leXu Ze kumazwe ahlukeneyo kunye nabavelisi bezixhobo ze-CNC bavelisa iinkcukacha ezahlukeneyo zeemveliso ezinomahluko omkhulu kwixabiso. Ngesiseko sokwanelisa uhlobo lolawulo, ukusebenza kunye nokukhethwa komsebenzi, kufuneka sihlalutye ngokubanzi umlinganiselo wexabiso lentsebenzo kwaye sikhethe izixhobo ze-CNC ezinomlinganiselo ophezulu wokusebenza-xabiso ukwenzela ukunciphisa iindleko.(5) Xa ukhetha isixhobo solawulo lwamanani esihlangabezana neemfuno zobugcisa, ukukhethwa kweenkonzo zobugcisa kufuneka kuthathelwe ingqalelo isidima somenzi, ukuba imiyalelo yemveliso kunye namanye amaxwebhu anokugqitywa ngumsebenzi wokuqeqesha kunye nokuqeqesha abasebenzi. Ngaba kukho isebe elikhethekileyo lenkonzo yobugcisa ukuze libonelele ngeendawo ezisecaleni kunye neenkonzo zokugcinwa kwangexesha ixesha elide ukuze kuphunyezwe izibonelelo zobugcisa nezoqoqosho. 2. Ukukhethwa kwe-feed drive (1) i-AC servo motor ikhethwayo, kuba xa kuthelekiswa ne-DC motor, i-rotor inertia incinci, impendulo eguquguqukayo ilungile, amandla aphumayo makhulu, isantya sokujikeleza siphezulu, isakhiwo silula, ixabiso liphantsi, kwaye indawo yesicelo ayikhawulelwanga. ( 2) Khetha i-servo motor yenkcazo efanelekileyo ngokubala ngokuchanekileyo iimeko zomthwalo ezongeziweyo kwi-motor shaft. ( 3 ) Umvelisi we-feed drive unikezela uluhlu lweeseti ezipheleleyo zeemveliso zeyunithi yokulawula isantya sokutya kunye ne-servo motor, ngoko emva kokuba imoto ye-servo ikhethiwe, iyunithi yokulawula isantya ehambelanayo ikhethwa kwincwadana yemveliso. 3. Ukukhethwa kwe-spindle drive (1) I-motor spindle engundoqo ikhethwayo, kuba ayinayo imiqobo yokutshintsha, isantya esiphezulu kunye nomthamo omkhulu njenge-DC spindle motor. Uluhlu oluqhubekayo lolawulo lwesantya samandla lukhulu, ingxolo iphantsi, kwaye ixabiso liphantsi. Okwangoku, i-85% yezixhobo zomatshini ze-CNC ziqhutywa yi-AC spindles emhlabeni. ( Isixhobo somatshini we-CNC) (2) Khetha i-spindle motor ngokwemigaqo elandelayo: 1 Amandla okusika abalwa ngokwezixhobo zoomatshini ezahlukeneyo, kunye nemoto ekhethiweyo kufuneka ihlangabezane nale mfuneko; I-2 Ngokwexesha elifunekayo lokunyuka kwe-spindle kunye ne-deceleration, kubalwa ukuba amandla ombane akufanele adlule ubuninzi bamandla okukhutshwa kwemoto; 3 Xa i-spindle ifuneka ukuba iqale rhoqo kwaye ibhuleki, inqanaba kufuneka libalwe. Ixabiso le-avareji yamandla alinako ukudlula umlinganiselo oqhubekayo wokuphuma kwamandla emoto;④ Kwimeko apho umphezulu ongaguqukiyo ufuneka ukuba ulawulwe, isixa samandla okusika afunekayo kulawulo lwesantya esingaguqukiyo somphezulu kunye namandla afunekayo ukukhawulezisa aya kuba ngaphakathi kuluhlu lwamandla anokubonelela ngemoto. (3) Umenzi we-spindle drive ubonelela ngothotho lweeseti ezipheleleyo zeemveliso zeyunithi yokulawula isantya sokusonta kunye nemoto yokuphotha, ke emva kokuba i-spindle motor ikhethiwe, iyunithi yokulawula isantya sokusonta ehambelanayo ikhethwa kwincwadana yemveliso. ( 4 ) Xa i-spindle iyadingeka kulawulo lwe-directional, ngokwemeko yokwenyani yesixhobo somatshini, khetha i-encoder yendawo okanye i-sensor yamagnetic ukuqonda ulawulo lwe-spindle direction. 4. Ukukhethwa kwezinto zokubona (1) Ngokwesicwangciso solawulo lwendawo yesistim yokulawula amanani, ukufuduka komgca wesixhobo somatshini kulinganiswa ngokuthe ngqo okanye ngokungathanga ngqo, kwaye izinto zokukhangela umgca okanye i-rotary zikhethiwe. Okwangoku, ulawulo lwe-semi-closed-loop lusetyenziswa ngokubanzi kwizixhobo zomatshini we-CNC, kunye nezinto zokulinganisa i-angle ejikelezayo (i-rotary transformers, i-pulse encoders) ikhethiwe. (2) Ngokweemfuno zezixhobo zomatshini ze-CNC zokubona ukuchaneka okanye ukukhawuleza, khetha indawo okanye izinto zokukhangela isantya (i-generator yokuvavanya, i-pulse encoders). Ngokuqhelekileyo, izixhobo zoomatshini abakhulu zihlangabezana neemfuno zesantya, kunye nokuchaneka okuphezulu, izixhobo zoomatshini ezincinci kunye neziphakathi ubukhulu becala zihlangabezana nokuchaneka. Isisombululo sesiqalelo esikhethiweyo sobhaqo ngokuqhelekileyo lulandelelwano lobukhulu obuphezulu kunokulungiswa kokuchaneka. ( 3 ) Okwangoku, eyona nto isetyenziswa ngokuqhelekileyo isixhobo sokufumanisa izixhobo zomatshini we-CNC (i-horizontal boring kunye nomatshini wokugaya) yi-photoelectric pulse encoder, ekhetha i-pulse encoder yeenkcukacha ezihambelanayo ngokwe-ball screw pitch yesixhobo somatshini we-CNC, ukuhamba okuncinci kwenkqubo ye-CNC, ukukhuliswa komyalelo kunye nokwandiswa kokufumanisa. ( 4) Xa ukhetha into yokufumanisa, kufuneka kuthathelwe ingqalelo ukuba isixhobo sokulawula amanani sinesekhethi ye-interface ehambelanayo.