Kwintsimi yokulungiswa komatshini wanamhlanje, oomatshini bokugaya kunye noomatshini bokugaya i-CNC zizinto ezimbini eziqhelekileyo kunye ezibalulekileyo zesixhobo somatshini, ezinomahluko omkhulu kwimisebenzi, izakhiwo, kunye neemeko zesicelo. Ukuze unikeze ukuqonda okunzulu kunye nokubanzi kwezi ntlobo zimbini zezixhobo zoomatshini, umenzi womatshini wokugaya we-CNC uya kukunika inkcazo ecacileyo ngezantsi.

1. Umahluko ongqongqo

Iimpawu zokuqina koomatshini bokomba

Umatshini wokugrumba wenzelwe ikakhulu ukumelana nemikhosi emikhulu emi nkqo, kunye namandla amancinci asecaleni. Oku kungenxa yokuba eyona ndlela iphambili yokuqhuba umatshini wokugrumba kukugrumba, kwaye i-drill bit ikakhulu ibhobhoza ecaleni kwendlela ethe nkqo ngexesha lokusebenza, kwaye amandla asetyenziswa kwi-workpiece agxininiswe kakhulu kwicala le-axial. Ngoko ke, isakhiwo somatshini wokugaya siye saqiniswa kwicala elithe nkqo ukuze kuqinisekiswe ukuzinza, ukunciphisa ukungcangcazela kunye nokuphambuka ngexesha lokugaya.

Nangona kunjalo, ngenxa yesakhono esibuthathaka soomatshini bokugrumba ukumelana namandla asecaleni, oku kukwanciphisa usetyenziso lwabo kwezinye iimeko ezinzima zomatshini. Xa kuyimfuneko ukwenza i-machining yecala kwi-workpiece okanye xa kukho ukuphazamiseka okukhulu kwecala ngexesha lokugaya, umatshini wokugaya awukwazi ukuqinisekisa ukuchaneka komatshini kunye nokuzinza.

Iimfuno zokuqina koomatshini bokungqusha be-CNC

Ngokungafaniyo noomatshini bokomba, oomatshini bokugaya be-CNC bafuna ukuqina okuhle kuba amandla avelisiweyo ngexesha lokugaya anzima kakhulu. Amandla okugaya akubandakanyi kuphela amandla amakhulu amileyo, kodwa kufuneka amelane nemikhosi emikhulu esecaleni. Ngethuba lenkqubo yokugaya, indawo yoqhagamshelwano phakathi kwe-milling cutter kunye ne-workpiece inkulu, kwaye isixhobo sijikeleza ngelixa sinqumla kwicala elithe tye, okubangela ukuba amandla okugaya asebenze kwiindlela ezininzi.

Ukuze ukwazi ukumelana neemeko ezinjalo zoxinzelelo oluntsonkothileyo, uyilo lolwakhiwo loomatshini bokungqusha be-CNC ludla ngokuqina kwaye luzinzile. Izinto eziphambili zesixhobo somatshini, ezifana nombhede, iikholomu, kunye neentsimbi zesikhokelo, zenziwe ngezinto eziphezulu zamandla kunye nezakhiwo eziphuculweyo zokuphucula ukuqina okupheleleyo kunye nokusebenza kokumelana nokungcangcazela. Ukuqina okuhle kwenza ukuba oomatshini bokugaya be-CNC bagcine ukuchaneka okuphezulu komatshini ngelixa bemelana nemikhosi emikhulu yokusika, ibenze bafanelekele ukusetyenzwa kweemilo ezahlukahlukeneyo ezintsonkothileyo kunye neenxalenye ezichanekileyo.

2.Ukwahluka kwesakhiwo

Iimpawu zesakhiwo koomatshini bokomba

Ukwakhiwa komatshini wokugaya kulula, kwaye kwiimeko ezininzi, nje ukuba ukondla okuthe nkqo kuphunyeziwe, kunokuhlangabezana neemfuno zokucwangcisa. Umatshini wokomba udla ngokuba nomzimba webhedi, ikholamu, ibhokisi yokuphotha, indawo yokusebenza, kunye nesixhobo sokutya.

Ibhedi yinxalenye esisiseko yomatshini wokugaya, esetyenziselwa ukuxhasa kunye nokufakela ezinye izinto. Ikholomu igxininiswe ebhedini ukunika inkxaso kwibhokisi ye-axle ephambili. Ibhokisi yokusonta ixhotyiswe ngesixhobo sokusonta kunye nesantya esiguquguqukayo, esisetyenziselwa ukuqhuba ukujikeleza kwebit drill. Ibhentshi yokusebenzela isetyenziselwa ukubeka izixhobo zokusebenza kwaye inokulungiswa lula kwaye ibekwe kwindawo. Indlela yokutya inoxanduva lokulawula intshukumo ye-axial feed ye bit drill ukufikelela kulawulo olunzulu lokomba.

Ngenxa yendlela elula yokucubungula oomatshini bokugaya, isakhiwo sabo silula kwaye iindleko zabo ziphantsi. Kodwa esi sakhiwo silula sikwanciphisa ukusebenza kunye noluhlu lokucubungula umatshini wokugaya.

Ukuqulunqwa kolwakhiwo koomatshini bokungqusha be-CNC

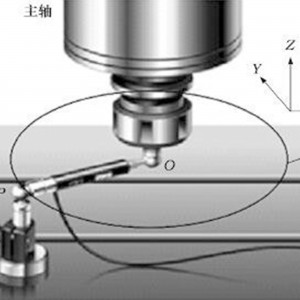

Ulwakhiwo koomatshini bokungqusha be-CNC bunzima ngakumbi. Ayifuni nje ukufezekisa ukondla okuthe nkqo, kodwa okona kubaluleke kakhulu, ifuna ukuba ne-horizontal longitudinal kunye nemisebenzi yokutya enqamlezayo. Oomatshini bokugaya i-CNC bahlala bequlunqwe ngamalungu afana nebhedi, ikholamu, itafile yokusebenzela, isali, ibhokisi yokuphotha, inkqubo ye-CNC, inkqubo yokuqhuba ukutya, njl.

Ibhedi kunye nekholomu zibonelela ngenkxaso ezinzileyo yesakhiwo somatshini. I-workbench inokuhamba ngokuthe tye ukufikelela kwisondlo esisecaleni. Isali ifakwe kwikholamu kwaye inokuqhuba ibhokisi yokuphotha ukuba ihambe ngokuthe nkqo, ifezekise ukondla kwe-longitudinal. Ibhokisi ye-spindle ixhotyiswe nge-spindles ephezulu yokusebenza kunye nezixhobo ezichanekileyo zokuhambisa isantya esiguquguqukayo ukuhlangabezana neemfuno zeendlela ezahlukeneyo zokucwangcisa.

Inkqubo ye-CNC yinxalenye yolawulo oluphambili lomatshini wokugaya we-CNC, onoxanduva lokufumana imiyalelo yeprogram kunye nokuguqula ibe yimiqondiso yokulawula intshukumo kwi-axis nganye yesixhobo somatshini, ukufezekisa izenzo ezichanekileyo zomatshini. Inkqubo ye-feed drive iguqula imiyalelo yenkqubo ye-CNC ibe yintshukumo yokwenyani yetafile yokusebenza kunye nesali ngokusebenzisa amacandelo afana neenjini kunye nezikrufu, iqinisekisa ukuchaneka komatshini kunye nomgangatho womphezulu.

3.Ukwenziwa komsebenzi

Umthamo wokulungisa umatshini wokugaya

Umatshini wokugrumba ikakhulu sisixhobo esisebenzisa i-drill bit ukugrumba kunye nokucwangcisa i-workpieces. Ngaphantsi kweemeko eziqhelekileyo, ukujikeleza kwe-drill bit is the motion main, ngelixa i-axial movement yomatshini wokugaya intshukumo yokutya. Oomatshini bokwemba banokwenza ngomngxuma, umngxuma oyimfama kunye neminye imisebenzi yomatshini kwi-workpieces, kwaye banokuhlangabezana neemfuno ezahlukeneyo zokuvula kunye nokuchaneka ngokutshintshela i-drill bits ezinobubanzi obuhlukeneyo kunye neentlobo.

Ukongeza, umatshini wokugaya unokwenza imisebenzi elula yokomba kunye nokucofa. Nangona kunjalo, ngenxa yokusikelwa umda kolwakhiwo kunye nokusebenza, oomatshini bokwemba abakwazi ukwenza imilo entsonkothileyo yomatshini kumphezulu wezinto zokusebenza, ezinje ngeendawo ezisicaba, iigrooves, iigiya, njl.

Uluhlu lomatshini wokugaya oomatshini be-CNC

Oomatshini bokugaya be-CNC banoluhlu olubanzi lwezakhono zokucwangcisa. Inokusebenzisa abasiki bemilling ukwenza umphezulu osicaba wezinto zokusebenza, kunye neemilo ezintsonkothileyo ezinje ngegrooves kunye negiya. Ukongeza, oomatshini bokugaya be-CNC banokuphinda baqhubekisele iiprofayili ezintsonkothileyo, ezinje ngeendawo ezigobileyo kunye neendawo ezingaqhelekanga, ngokusebenzisa izixhobo ezikhethekileyo zokusika kunye neendlela zokucwangcisa.

Xa kuthelekiswa noomatshini bokugrumba, oomatshini bokugaya be-CNC banokusebenza okuphezulu komatshini, isantya esikhawulezayo, kwaye banokufezekisa ukuchaneka okuphezulu komatshini kunye nomgangatho womphezulu. Oku kwenze ukuba oomatshini bokugaya be-CNC basetyenziswe ngokubanzi kwimimandla efana nokuveliswa kokungunda, i-aerospace, kunye nezixhobo zemoto.

4.Izixhobo kunye nezixhobo

Izixhobo kunye nezixhobo zoomatshini bokwemba

Isixhobo esiphambili esisetyenziswe kumatshini wokugaya i-drill bit, kwaye imilo kunye nobukhulu be-drill bit ekhethiweyo ngokweemfuno zokucubungula. Kwinkqubo yokugaya, izixhobo ezilula ezifana neepliers, i-V-blocks, njl. Ngenxa yokuba amandla acutshungulwa ngumatshini wokugaya agxininiswe kakhulu kwi-axial direction, uyilo lwe-fixture lulula, ngokukodwa ukuqinisekisa ukuba i-workpiece ayiyi kuhamba okanye ijikeleze ngexesha lokugaya.

Izixhobo kunye nokulungiswa koomatshini bokungqusha be-CNC

Kukho iintlobo ezahlukeneyo zezixhobo zokusika ezisetyenziswe kumatshini wokugaya i-CNC, kubandakanywa i-ball end mill, i-end mill, i-face mill, njl. Ukongeza kwii-milling cutters eziqhelekileyo. Iindidi ezahlukeneyo zezixhobo zokusika zifanelekile kwiindlela ezahlukeneyo zokucwangcisa kunye neemfuno zemilo. Kwi-CNC yokugaya, iimfuno zoyilo lwezixhobo ziphezulu, kwaye izinto ezinjengokusasazwa kwamandla okusika, ukuchaneka kwendawo yokusebenza, kunye nobukhulu bamandla okudibanisa kufuneka kuthathelwe ingqalelo ukuze kuqinisekiswe ukuba i-workpiece ayifumani ukufuduka kunye nokuguqulwa ngexesha lenkqubo yomatshini.

Ukuze kuphuculwe ukusebenza kakuhle komatshini kunye nokuchaneka, oomatshini bokugaya be-CNC bahlala besebenzisa izixhobo ezikhethekileyo kunye nezixhobo, ezifana nezixhobo ezidibeneyo, izixhobo ze-hydraulic, njl. Ngelo xesha, oomatshini bokugaya i-CNC banokufikelela kwakhona ukutshintshwa ngokukhawuleza kwezixhobo zokusika ezahlukeneyo ngokusebenzisa izixhobo ezizenzekelayo zokutshintsha izixhobo, ukuphucula ngakumbi ukuguquguquka kunye nokusebenza kakuhle kokulungiswa.

5. Ukucwangcisa nokuSebenza

Ukucwangcisa kunye nokusebenza koomatshini bokwemba

Inkqubo yomatshini wokugaya ilula, ngokuqhelekileyo ifuna kuphela ukusetwa kweeparamitha ezifana nobunzulu bokomba, isantya, kunye nesantya sokutya. Abaqhubi banokugqiba inkqubo yomatshini ngokusebenza ngesandla isibambo okanye iqhosha lesixhobo somatshini, kwaye banokusebenzisa inkqubo ye-CNC elula yokucwangcisa kunye nokulawula.

Ngenxa yobuchwephesha obulula bokucutshungulwa koomatshini bokwemba, ukusebenza kulula, kwaye iimfuno zobugcisa zabaqhubi ziphantsi. Kodwa oku kukwanciphisa ukusetyenziswa koomatshini bokomba kwinxalenye entsonkothileyo yokusetyenzwa.

Ukucwangcisa kunye nokusebenza koomatshini bokugaya be-CNC

Ukucwangciswa koomatshini bokungqusha be-CNC kunzima kakhulu, kufuna ukusetyenziswa kwesoftware yenkqubo yobungcali efana ne-MasterCAM, i-UG, njl., ukuvelisa iinkqubo zomatshini ezisekelwe kwimizobo kunye neemfuno zomatshini zamacandelo. Ngexesha lenkqubo yenkqubo, izinto ezininzi ezifana nendlela yesixhobo, iiparamitha zokusika, kunye nolandelelwano lwenkqubo kufuneka ziqwalaselwe ukuqinisekisa ukuchaneka komatshini kunye nokusebenza kakuhle.

Ngokumalunga nokusebenza, oomatshini bokugaya be-CNC bahlala bexhotyiswe ngezikrini zokuchukumisa okanye iipaneli zokusebenza. Abaqhubi kufuneka baqhelane ne-interface yokusebenza kunye nemisebenzi yenkqubo ye-CNC, bakwazi ukufaka ngokuchanekileyo imiyalelo kunye neeparitha, kwaye babeke iliso kwimeko ngexesha lenkqubo yomatshini. Ngenxa yobuchwephesha bokulungisa obuntsonkothileyo koomatshini bokugaya i-CNC, kukho imfuno ephezulu yenqanaba lobugcisa kunye nolwazi lobuchwephesha lwabaqhubi, olufuna uqeqesho olukhethekileyo kunye nokuziqhelanisa ukuze uphumelele kakuhle.

6, Indawo yosetyenziso

Iimeko zokusetyenziswa koomatshini bokomba

Ngenxa yobume bayo obulula, ixabiso eliphantsi, kunye nokusebenza kakuhle, oomatshini bokwemba basetyenziswa ngokubanzi kwezinye iindibano zocweyo ezincinci zokulungisa oomatshini, iindibano zocweyo zokulungisa, kunye nemizi yokulungisa umntu ngamnye. Isetyenziselwa ikakhulu ukucubungula iinxalenye ezinezakhiwo ezilula kunye neemfuno ezichanekileyo ezisezantsi, ezifana neendawo zohlobo lomngxuma, iindawo ezidibanisayo, njl.

Kwamanye amashishini okuvelisa ngobuninzi, oomatshini bokwemba bangasetyenziselwa ukusetyenzwa kweenkqubo ezilula, njengokugrumba imingxuma kwiphepha lesinyithi. Nangona kunjalo, ngokuchaneka okuphezulu kunye nokulungiswa kweengxenye ezintsonkothileyo, oomatshini bokomba abanakuhlangabezana neemfuno.

Umda wokusetyenziswa koomatshini bokungqusha be-CNC

Oomatshini bokugaya i-CNC baye basetyenziswa ngokubanzi kwiinkalo ezifana nokuvelisa i-mold, i-aerospace, i-automotive components, izixhobo zombane, njl. Ingasetyenziselwa ukucubungula imilo eyahlukeneyo eyinkimbinkimbi, iindawo ezichanekileyo, iibhokisi zebhokisi, njl., kwaye inokuhlangabezana neemfuno zemveliso yanamhlanje yokuchaneka okuphezulu kunye nokusebenza okuphezulu.

Ngokukodwa kwamanye amashishini okuvelisa akumgangatho ophezulu, oomatshini bokugaya be-CNC baye baba sisixhobo esibalulekileyo esibalulekileyo, badlala indima ebalulekileyo ekuphuculeni umgangatho wemveliso, ukunciphisa imijikelo yemveliso, kunye nokunciphisa iindleko.

7, Ukuthelekisa imizekelo yomatshini

Ukuze ukubonisa intuitively ngakumbi umahluko kwiziphumo machining phakathi koomatshini bokomba kunye noomatshini bokugaya CNC, imizekelo emibini ethile yomatshini iya kuthelekiswa ngezantsi.

Umzekelo 1: Ukwenza icwecwe elilula leplate

Ukucutshungulwa komatshini wokugaya: Okokuqala, lungisa i-workpiece kwi-workbench, khetha i-drill bitana efanelekileyo, ulungelelanise ubunzulu bokugaya kunye nesantya sokutya, kwaye emva koko uqalise umatshini wokugaya ukuqhubela phambili. Ngenxa yokuba oomatshini bokwemba banokwenza kuphela ukugrumba ngokuthe nkqo, iimfuno zokuchaneka kwendawo yomngxuma kunye nomgangatho womphezulu azikho phezulu, kwaye ukusebenza kakuhle kuncinci.

CNC yokusila umatshini processing: Xa usebenzisa umatshini wokusila CNC ukuze processing, inyathelo lokuqala imodeli amacandelo 3D nokuvelisa inkqubo machining ngokweemfuno inkqubo machining. Emva koko faka i-workpiece kwindawo ezinikeleyo, faka inkqubo yomatshini ngokusebenzisa inkqubo ye-CNC, kwaye uqalise isixhobo somatshini wokwenza. Oomatshini bokugaya be-CNC banokufezekisa ukucwangciswa kwangaxeshanye kwimingxuma emininzi ngokucwangcisa, kwaye kunokuqinisekisa ukuchaneka kwendawo kunye nomgangatho womphezulu wemingxuma, ukuphucula kakhulu ukusebenza kakuhle komatshini.

Umzekelo 2: Ukulungisa indawo yokungunda entsonkothileyo

Ukusetyenzwa koomatshini bokugrumba: Kwiindawo zokubumba ezinobumba obuntsonkothileyo, oomatshini bokomba baphantse bangakwazi ukugqiba imisebenzi yokulungisa. Nokuba kusetyenzwa ngeendlela ezikhethekileyo, kunzima ukuqinisekisa ukuchaneka komatshini kunye nomgangatho womphezulu.

Ukusetyenzwa komatshini wokusila we-CNC: Ngokusebenzisa imisebenzi enamandla yoomatshini bokusila be-CNC, kuyenzeka ukuba uqale wenze umatshini orhabaxa kwiindawo zokungunda, ususe uninzi lobuninzi obugqithileyo, emva koko wenze ukuchaneka kwesiqingatha kunye nokuchaneka komatshini, ekugqibeleni ufumane iindawo zokungunda ezichanekileyo nezikumgangatho ophezulu. Ngexesha lenkqubo yomatshini, iintlobo ezahlukeneyo zezixhobo zingasetyenziswa kwaye iiparamitha zokusika zinokulungiswa ukuze kuphuculwe ukusebenza kakuhle komatshini kunye nomgangatho womphezulu.

Ngokuthelekisa le mizekelo mibini ingasentla, kunokubonwa ukuba oomatshini bokwemba bafanelekele ukusetyenzwa komngxuma olula, ngelixa oomatshini bokugaya be-CNC bekwazi ukujongana neemilo ezahlukeneyo ezintsonkothileyo kunye namalungu achanekileyo.

8, Isishwankathelo

Isishwankathelo, kukho ukungafani okuphawulekayo phakathi koomatshini bokugaya kunye noomatshini bokugaya i-CNC ngokwemiqathango yokuqina, isakhiwo, imisebenzi yokucubungula, izixhobo zokusebenza, iinkqubo zokusebenza, kunye neendawo zokusebenzisa. Umatshini wokugaya unesakhiwo esilula kunye neendleko eziphantsi, kwaye ufanelekile ukugaya okulula kunye nokuqhutyelwa kokwandisa umngxuma; Oomatshini bokugaya be-CNC baneempawu zokuchaneka okuphezulu, ukusebenza kakuhle okuphezulu, kunye nokusebenza ngeendlela ezininzi, ezinokuhlangabezana neemfuno zemveliso yanamhlanje yokulungiswa kwenxalenye enzima.

Kwimveliso yangempela, oomatshini bokugaya okanye oomatshini bokugaya i-CNC kufuneka bakhethwe ngokufanelekileyo ngokusekelwe kwimisebenzi ethile yokucubungula kunye neemfuno zokufezekisa umphumo ongcono wokusebenza kunye neenzuzo zoqoqosho. Kwangaxeshanye, kunye nenkqubela phambili eqhubekayo yetekhnoloji kunye nophuhliso loshishino lokuvelisa, oomatshini bokomba kunye noomatshini bokugaya be-CNC nabo bahlala bephucula kwaye begqibelela, bebonelela ngenkxaso yobugcisa eyomeleleyo kuphuhliso lweshishini lokulungisa oomatshini.