Kwinkalo yokwenziwa kwemizi-mveliso yanamhlanje, iiziko oomatshini nkqosisixhobo esibalulekileyo. Ibonelela ngenkxaso eyomeleleyo yokusetyenzwa kwee-workpieces ezahlukeneyo kunye nokusebenza kwayo okukodwa kunye nokusetyenziswa okubanzi.

I. Imisebenzi ephambili yeziko lomatshini elithe nkqo

Umsebenzi wokugaya

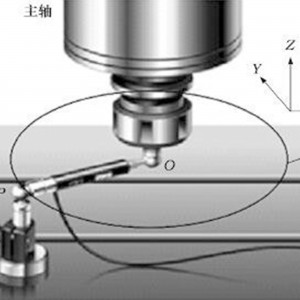

Iiziko oomatshini nkqoinokugqiba ngokugqwesileyo imisebenzi yeenqwelomoya zokusila, iigrooves kunye nemigangatho, kwaye inokwenza imingxuma enzima kunye namaqhuma. Ngokusebenzisa isixhobo sokusila esifakwe kwi-spindle, phantsi kolawulo oluchanekileyo lweprogram yomatshini, isebenzisana ne-workpiece workbench ehamba kwicala lama-axes amathathu okulungelelanisa i-X, i-Y kunye ne-Z ukuphumeza ukubunjwa okuchanekileyo kwendawo yokusebenza ukuhlangabezana nomgangatho ofunekayo ngumzobo.

Umsebenzi wokulawula iphuzu

Umsebenzi wayo wokulawula inqaku ujolise ikakhulu ekuqhutyweni komngxuma we-workpiece, ukugubungela imisebenzi eyahlukeneyo yokucubungula imingxuma efana nokumisa iziko lokugaya, ukugaya, ukubuyisela kwakhona, ukusasaza, ukuxhamla kunye nokudinwa, ukubonelela ngesisombululo esisebenzayo sokulungiswa komngxuma we-workpiece.

Umsebenzi wolawulo oluqhubekayo

Ngoncedo lwe-linear interpolation, i-arc interpolation okanye i-complex curve interpolation movement, iiziko oomatshini nkqoinokusila kwaye iqhubekise indiza kunye nemigangatho egobileyo yendawo yokusebenza ukuze iqonde iimfuno zokusetyenzwa kweemilo ezintsonkothileyo.

Umsebenzi wembuyekezo yeradiyasi yesixhobo

Lo msebenzi unentsingiselo enkulu. Ukuba udwelisa ngokuthe ngqo ngokomgca wecontour yomsebenzi, eyona khokhoni iya kuba lixabiso elikhulu leradiyasi yesixhobo xa usenza i-contour yangaphakathi, kunye nexabiso leradiyasi yesixhobo esincinci xa kusenziwa mashini i-contour yangaphandle. Ngokusebenzisa imbuyekezo yeradiyasi yesixhobo, inkqubo yolawulo lwamanani ibala ngokuzenzekelayo i-trajectory yeziko lesixhobo, esitenxa kwixabiso leradiyasi yesixhobo se-contour ye-workpiece, ukuze kuqhutywe ngokuchanekileyo i-contour ehlangabezana neemfuno. Ngaphaya koko, lo msebenzi unokuhlawulela ukunxitywa kwesixhobo kunye neempazamo zobuchwephesha ukuqonda inguqu ukusuka kumatshini omdaka ukuya ekugqityweni.

Umsebenzi wembuyekezo yobude besixhobo

Ukutshintsha isixa sembuyekezo yobude besixhobo asikwazi ukuhlawulela kuphela ixabiso lokutenxa ubude besixhobo emva kokuba isixhobo sitshintshiwe, kodwa kwakhona ulawule indawo yendiza yenkqubo yokusika ukulawula ngokufanelekileyo ukuchaneka kwendawo ye-axial yesixhobo.

Umsebenzi wokuqhuba umjikelo osisigxina

Ukusetyenziswa kwemiyalelo yokucwangcisa umjikelo osisigxina kwenza lula inkqubo yokucubungula, ukunciphisa umthwalo wokucwangcisa, kunye nokuphucula ukusebenza kakuhle.

Umsebenzi wenkqutyana

Kwiindawo ezinemilo efanayo okanye efanayo, ibhalwa njenge-subroutine kwaye ibizwa ngokuba yiprogram ephambili, enokwenza lula kakhulu ukwakhiwa kweprogram. Le modularization yeprogram yahlulwe kwiimodyuli ezahlukeneyo ngokwenkqubo yenkqubo yokucubungula kwaye ibhalwe kwinkqutyana, kwaye emva koko ibizwe yinkqubo ephambili yokugqiba ukusetyenzwa kwe-workpiece, eyenza inkqubo ibe lula ukuyiqhuba kunye nokulungiswa kweempazamo, kwaye iphinda ibe luncedo ekuphuculeni inkqubo yokucubungula.

Umsebenzi okhethekileyo

Ngokuqwalasela isoftware yokukopa kunye nesixhobo sokukopisha, ukuskena kunye nokuqokelela idatha yezinto eziphathekayo ngokudityaniswa nabenzi boluvo, iinkqubo ze-NC zenziwa ngokuzenzekelayo emva kokulungiswa kwedatha ukuqonda ukukopishwa kunye nokubuyisela umva umsebenzi we-workpieces. Emva kokuqwalasela isoftware ethile kunye nehardware, umsebenzi wokusetyenziswa kweziko lomatshini elithe nkqo uye wandiswa ngakumbi.

II. Ukusetyenzwa komda weziko lomatshini elithe nkqo

Ukusetyenzwa komphezulu

Kubandakanya ukugaya inqwelomoya ethe tye (XY), inqwelomoya elungileyo (XZ) kunye nenqwelomoya esecaleni (YZ) yesixhobo sokusebenza. Kufuneka usebenzise kuphela i-axis-axis ezimbini kunye nesiqingatha-elawulwa nkqo kwiziko lomatshini ukuze ugqibezele imisebenzi yokugaya ezi nqwelomoya.

Ukusetyenzwa komphezulu

Ukusila iindawo ezintsonkothileyo ezigobileyo, i-axis emithathu okanye ngaphezulu edityaniswe neshaft-edityaniswe nkqo kwiziko lomatshini elithe nkqo liyafuneka ukuhlangabezana nokuchaneka okuphezulu komatshini kunye neemfuno zokumila.

III. Izixhobo zeziko lomatshini elithe nkqo

Umphathi

Umgangatho wendalo yonke uquka iipliyisi zomlomo osicaba, iikomityi zokufunxa imagnethi kunye nezixhobo zokucinezela iipleyiti. Kwimiyinge ephakathi, enkulu okanye i-workpieces enzima, izixhobo ezidibeneyo kufuneka ziyilwe. Ukuba ukulungiswa kwe-pneumatic kunye ne-hydraulic isetyenzisiweyo kwaye ukulayishwa ngokuzenzekelayo kunye nokulayishwa kufezekiswa ngokulawulwa kweprogram, kuya kuphucula kakhulu ukusebenza kakuhle kunye nokunciphisa amandla omsebenzi.

Umsiki

Izixhobo zokusila ezisetyenziswa ngokuqhelekileyo ziquka abasiki besiphelo sokusila, abasiki bokuyila, abasiki bokuyila kunye nezixhobo zokusila. Ukukhethwa kunye nokusetyenziswa kwezi zixhobo kufuneka kumiselwe ngokwemisebenzi ethile yomatshini kunye nezixhobo zokusebenza ukuqinisekisa umgangatho wokucubungula kunye nokusebenza kakuhle.

IV. Izinto ezilungileyo zeiziko oomatshini nkqo

Ukuchaneka okuphezulu

Iyakwazi ukuqonda ukuchaneka okuphezulu kwaye iqinisekise ukuba ubungakanani kunye nokuchaneka kwemilo ye-workpiece ihlangabezana neemfuno ezingqongqo.

Ukuzinza okuphezulu

Ulwakhiwo lomelele kwaye luzinzile, olunokugcina ukusebenza kakuhle ngexesha lokusebenza kwexesha elide kunye nokulungelelanisa kwiindawo ezahlukeneyo zokucubungula.

Ukuguquguquka okunamandla

Iindidi ezahlukeneyo zemisebenzi yokucubungula inokuqhutywa ukuhlangabezana nokutshintsha kwezinto ezahlukeneyo zokusebenza kunye neemfuno zemveliso.

Ukusebenza okulula

Emva koqeqesho oluthile, umqhubi unokwazi iindlela zakhe zokusebenza kunye nokuphucula ukusebenza kakuhle kwemveliso.

Ukuguquguquka okuhle

Sebenza nezinye izixhobo ukuphucula ukusebenza kakuhle kunye nokulungelelaniswa kwenkqubo yokuvelisa ngokubanzi.

Isebenza kakuhle emalini

Nangona utyalo-mali lokuqala lunokuba luphezulu, ukusetyenzwa kwayo ngokufanelekileyo kunye neendleko zokugcinwa okuphantsi kwenza ukuba kube neendleko ezisebenzayo ekusebenziseni ixesha elide.

V. Indawo yesicelo yeziko lomatshini elithe nkqo

I-Aerospace

Isetyenziselwa ukwenza izinto ezintsonkothileyo ze-aerospace, ezinje ngeenjini ze-injini, izakhiwo zomzimba, njl.

Ukwenziwa kweemoto

Ukuveliswa kwezinto eziphambili ezifana neenjini kunye nokuhanjiswa kweemoto, kunye nokubumba komzimba, njl.

Ukwenziwa koomatshini

Lungiselela zonke iintlobo zamalungu oomatshini, njengeegiya, iishafts, njl.

Izixhobo zombane

Ukuvelisa amaqokobhe ezixhobo zombane, iinxalenye zesakhiwo sangaphakathi, njl.

Izixhobo zonyango

Ukuvelisa izixhobo zonyango ezichaneke kakhulu.

Ngelizwi, njengenye yezixhobo ezibalulekileyo kushishino lwanamhlanje, iziko lomatshini elithe nkqo lidlala indima engenakuphinda ithathelwe indawo kwiinkalo ezahlukeneyo kunye nemisebenzi yalo eyahlukeneyo, uluhlu olubanzi lokusetyenzwa, izixhobo ezinobunkunkqele kunye neenzuzo ezininzi. Ngenkqubela phambili eqhubekayo yesayensi kunye nobuchwepheshe kunye notshintsho oluqhubekayo lwemfuno yemizi-mveliso, iziko lomatshini elithe nkqo liya kuqhubeka liphuhlisa kwaye liphucule, lifaka amandla amatsha kunye namandla kuphuhliso lweshishini lemveliso.

Kwixesha elizayo, sinokulindela ukuba iziko lomatshini elithe nkqo lenze impumelelo enkulu kubukrelekrele kunye ne-automation. Ngokudityaniswa kwetekhnoloji ye-sensor ephucukileyo, ubukrelekrele bokwenziwa kunye nedatha enkulu, inkqubo ekrelekrele yokujonga inkqubo kunye nokwenza ngcono kuyaphunyezwa. Kwangaxeshanye, ngophuhliso lwesayensi yezinto, uphando kunye nophuhliso lwezixhobo ezitsha kunye nezixhobo ziya kuphucula ngakumbi ukusebenza kunye nokusebenza kakuhle kwamaziko omatshini amileyo. Ukongeza, phantsi kwendlela eqhelekileyo yokwenziwa kohlaza, amaziko omatshini athe nkqo nawo aya kuphuhlisa kwicala lokonga amandla kunye nokukhuselwa kwendalo ukuhlangabezana neemfuno zophuhliso oluzinzileyo.

Millingmachine@tajane.comLe yidilesi yam yemeyile. Ukuba uyayifuna, ungandithumelela i-imeyile. Ndilinde ileta yakho eseTshayina.