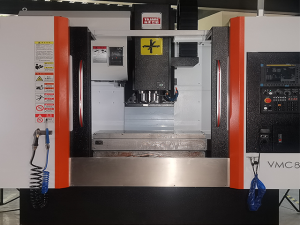

Njengesixhobo esiyimfuneko nesibalulekileyo kwimveliso yanamhlanje yemizi-mveliso,Umatshini wokungqusha we-CNCinempembelelo ebalulekileyo ekusebenzeni kakuhle kunye nomgangatho wemveliso. Ukuze kuqinisekiswe ukuba umatshini wokusila we-CNC unokusebenza ngokuzinzileyo ixesha elide, indlela yokulondoloza echanekileyo ibalulekile. Makhe sixoxe ngeendawo zokugcina zeoomatshini bokusila be-CNCngobunzulu ngeUmatshini wokungqusha we-CNCabavelisi.

I. Ukugcinwa kwenkqubo yolawulo lwamanani

Inkqubo ye-CNC yinxalenye engundoqo yeUmatshini wokungqusha we-CNC, kwaye ukugcinwa kwayo okungqongqo kubaluleke kakhulu. Okokuqala, kufuneka kuqhutywe ngokuhambelana ngokungqongqo kunye nemigaqo yokusebenza kunye nokugcinwa kwenkqubo yokulawula amanani ukuze kuqinisekiswe ukusebenza okuqhelekileyo kokutshatyalaliswa kobushushu kunye nenkqubo yokuphefumula kwekhabhinethi yombane. Ukutshatyalaliswa kobushushu obungalunganga kunye nokungena komoya kunokubangela ukuba inkqubo idlulele, ngaloo ndlela ichaphazele uzinzo kunye nobomi benkqubo.

Ngexesha elifanayo, kuyimfuneko ukunciphisa ukusebenza kwezixhobo ezingadingekile zokungena kunye nemveliso kunye nokugcina nokuhlola rhoqo. Ibrashi yemoto ye-DC kunye ne-brushless DC motor iya kuphelelwa kancinci ngexesha lokusetyenziswa. Xa inguqu yokunxiba, kufuneka itshintshwe ngexesha, kungenjalo iya kuchaphazela ukusebenza kwemoto kwaye ibangele umonakalo kwimoto. KubaCNC lathes, oomatshini bokusila be-CNC, amaziko omatshini kunye nezinye izixhobo, ukuhlolwa okubanzi kufuneka kwenziwe kanye ngonyaka.

Kwiibhodi zesekethe eziprintiweyo zexesha elide kunye neebhodi zesekethe zokugcinwa kwebhetri, kufuneka zitshintshwe rhoqo kwaye zifakwe kwinkqubo yokulawula amanani ixesha elithile lokuthintela umonakalo. Oku kunokugcina ibhodi yesekethe ikwimeko entle kwaye iqinisekise ukuba inokusebenza ngokuqhelekileyo xa kuyimfuneko.

II. Ukugcinwa kwamalungu oomatshini

Ukulungelelaniswa kwebhanti ye-spindle drive

Kubaluleke kakhulu ukulungelelanisa rhoqo ukuqina kwebhanti ye-spindle drive. Ibhanti evulekileyo inokukhokelela ekutyibilikeni, okuchaphazela isantya sokujikeleza kunye nokuhanjiswa kwetorque ye-spindle, kwaye ngaloo ndlela ichaphazela ukuchaneka komatshini kunye nokusebenza kakuhle. Le meko inokuthintelwa ngokulungelelanisa ukuqina kwebhanti ngokufanelekileyo.

Ukugcinwa kwetanki yobushushu obungaguqukiyo bokuthambisa i-spindle

Kuyimfuneko ukujonga itanki yeqondo lokushisa rhoqo le-lubrication ye-spindle, lungisa uluhlu lweqondo lokushisa, uzalise ioli ngexesha, kwaye ucoce isihluzo. Ukuthambisa okulungileyo kunye nokulawula ubushushu obuqhubekayo kunceda ukugcina imeko efanelekileyo yokusebenza ye-spindle, ukunciphisa ukuguga kunye nokuguqulwa kwe-thermal, kunye nokuphucula ukuchaneka kokucubungula.

Ingqalelo kwisixhobo sokugoqa sokuphotha

Emva kokusetyenziswa kwexesha elideUmatshini wokungqusha we-CNC, isixhobo sokugoqa sinokuba neengxaki ezifana neenotshi, eziya kuba nefuthe ekubambeni isixhobo. Ke ngoko, ukufuduswa kwepiston ye-hydraulic cylinder piston kufuneka kuhlengahlengiswe kwangexesha ukuze kuqinisekiswe ukuba isixhobo sinokuqiniswa ngokuqinileyo ukuphepha ukukhulula okanye ukuwa ngexesha lokucubungula.

Ukugcinwa kweeperi zemisonto yebhola

Rhoqo jonga ubume bebhola ephothiweyo ngesikrufu kwaye ulungelelanise isithuba se-axial seperi esithungelweyo. Oku kunokuqinisekisa ukuchaneka kokudluliselwa kwe-reverse kunye nokuqina kwe-axial, kunye nokuqinisekisa ukuchaneka kunye nokuzinza kwesixhobo somatshini ngexesha lokuhamba kwesondlo. Ngexesha elifanayo, kuyimfuneko ukujonga rhoqo ukuba ukudibanisa phakathi kwe-screw kunye nebhedi kukhululekile. Ukuba kukho ukukhululeka, kufuneka kuqiniswe ngexesha. Emva kokuba isixhobo sokukhusela intambo sonakaliswe, kufuneka sitshintshwe ngokukhawuleza ukukhusela uthuli okanye iitshiphusi ukuba zingangeni kwisibini esinentambo kwaye sibangele umonakalo.

III. Ukugcinwa kwe-hydraulic kunye ne-pneumatic systems

Iinkqubo zeHydraulic kunye ne-pneumatic nazo zidlala indima ebalulekileyo kumatshini wokugaya i-CNC. Ukugcinwa rhoqo kwe-hydraulic kunye ne-pneumatic systems kubalulekile.

Okokuqala, isihluzo okanye isihluzo kufuneka sicocwe okanye sitshintshwe ukuze kuqinisekiswe ukuba i-oyile kunye negesi ye-hydraulic kunye ne-pneumatic systems zicocekile. Ioli ecocekileyo kunye negesi inokunciphisa ukungcola kunye nokungcola kwinkqubo, kunye nokunciphisa umngcipheko wokugqoka kunye nokungaphumeleli kwamacandelo.

Okwesibini, ukuhlolwa kokuvavanywa kweoli eqhelekileyo kunye nokutshintshwa kweoli ye-hydraulic kwinkqubo yoxinzelelo kufuneka yenziwe. Ioyile yeHydraulic iya kuwohloka ngokuthe ngcembe ngexesha lokusetyenziswa kwaye ilahlekelwe ngumsebenzi wayo ofanelekileyo. Ukutshintshwa rhoqo kweoli ye-hydraulic kunokuqinisekisa ukusebenza okuqhelekileyo kwenkqubo ye-hydraulic kunye nokuphucula ukuthembeka kwenkqubo.

Ukongezelela, isihluzo somoya kufuneka sigcinwe rhoqo ukuze kuqinisekiswe ukuba umoya ongena kwi-pneumatic system ucocekile kwaye womile. Ngexesha elifanayo, ukuchaneka komatshini kufuneka kuhlolwe kwaye kulinganiswe rhoqo ukuze kuqinisekiswe ukuba isixhobo somatshini sisenako ukugcina amandla okusebenza ngokuchanekileyo emva kokusetyenziswa kwexesha elide.

IV. Ezinye iindawo zokugcina

Ukongeza kule miba ingentla yolondolozo, kukho eminye imiba ekufuneka iqwalaselwe.

Okokuqala, indawo yokusebenza yomatshini wokungqusha we-CNC kufuneka igcinwe icocekile kwaye icocekile. Gwema uthuli, i-debris, njl. ukungena kwisixhobo somatshini, esinempembelelo ekuchanekeni nasekusebenzeni kwesixhobo somatshini.

Okwesibini, umqhubi kufuneka asebenze ngokungqongqo ngokuhambelana neenkqubo zokusebenza ukuze agweme umonakalo kwisixhobo somatshini esibangelwa ukungahambi kakuhle. Ngexesha elifanayo, kuyimfuneko ukuqinisa ukuqeqeshwa kwabaqhubi kunye nokuphucula izakhono zabo zokusebenza kunye nolwazi lokulondoloza.

Ukongezelela, kuyimfuneko ukuseka iirekhodi zokugcinwa ngokugqibeleleyo kunye neefayile. Rekhoda umxholo, ixesha, abasebenzi kunye nolunye ulwazi lwesondlo ngasinye ngokweenkcukacha ukwenzela ukulandelelwa kunye nohlalutyo. Ngokuhlalutya iirekhodi zokugcinwa, iingxaki kunye neengozi ezifihliweyo zezixhobo zoomatshini zinokufumaneka ngexesha kwaye amanyathelo ahambelanayo anokuthathwa ukuze azisombulule.

Ngelizwi, ukugcinwa koomatshini bokugaya i-CNC ngumsebenzi ocwangcisiweyo kunye nocokisekileyo, ofuna iinzame ezidibeneyo zabaqhubi kunye nabasebenzi bokulondoloza. Ngokusebenzisa indlela yokulondoloza echanekileyo, ubomi benkonzo yomshini wokugaya i-CNC bungakwandiswa, ukuchaneka kwayo kunye nokusebenza kakuhle kunokuphuculwa, kwaye ukuveliswa kunye nophuhliso lwamashishini kunokubonelelwa ngenkxaso eqinile. Kwinkqubo yokugcinwa, umsebenzi kufuneka uqhutywe ngokuhambelana ngokungqongqo kunye neemfuno kunye neenkcukacha zomenzi ukuqinisekisa ukusebenza kunye nokhuseleko lomsebenzi wokulondoloza. Kwangaxeshanye, kufuneka siqhubeke sifunda kwaye silawule ubugcisa obutsha bokulondolozwa kunye neendlela, siphucula rhoqo inqanaba lolondolozo, kwaye sikhaphe ukusebenza kakuhle koomatshini bokungqusha be-CNC.

Millingmachine@tajane.com This is my email address. If you need it, you can email me. I’m waiting for your letter in China.