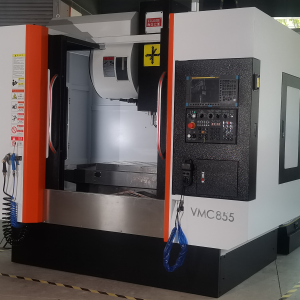

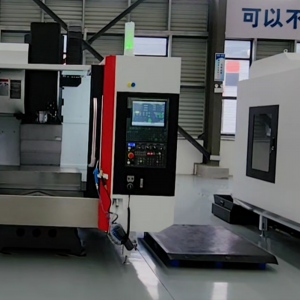

Kwishishini lemveliso yanamhlanje,oomatshini bokusila be-CNCzisetyenziswe ngokubanzi ngenxa yeenzuzo zazo ezibalulekileyo njengokuchaneka okuphezulu, ukusebenza kakuhle okuphezulu, kunye nenqanaba eliphezulu lokuzenzekelayo. Nangona kunjalo, ukuze kusetyenziswe ngokupheleleyo ukusebenza koomatshini bokugaya i-CNC kunye nokufezekisa umgangatho ophezulu kunye nokusebenza kakuhle, ukukhethwa kwezixhobo zokusika kubalulekile. Njengenxalenye ephambili ebandakanyeka ngokuthe ngqo ekusikeni, ukhetho olufanelekileyo lwezixhobo zokusika luya kuchaphazela ngokuthe ngqo umgangatho kunye nokusebenza kakuhle kwemveliso yemveliso yokugqibela. Ngokusekwe koku, eli nqaku liza kuphonononga kwiingongoma ezifanelekileyo zokukhetha izixhobooomatshini bokusila be-CNC.

1, Iimfuno zokusika izixhobo kumatshini wokusila we-CNC

Ngenxa yokuchaneka kwayo okuphezulu, isantya esiphezulu, kunye nenqanaba eliphezulu lokuzenzekelayo,oomatshini bokusila be-CNCbabeke phambili iimfuno ezingqongqo kwizixhobo ezisetyenzisiweyo. Ukuze kuqinisekiswe umgangatho womatshini kunye nokuphucula ukusebenza kakuhle kwemveliso, izixhobo zomatshini wokungqusha we-CNC kufuneka zibe nezi mpawu zilandelayo:

(1) Ukuthembeka kunye nokuqina

Okokuqala, izixhobo zokusika kufuneka zibe nokuthembeka okuphezulu kunye nokuqina. Kwinkqubo eqhubekayo yomatshini weoomatshini bokusila be-CNC, isixhobo kufuneka simelane namandla amakhulu okusika kunye nemithwalo ye-thermal ixesha elide. Ukuba ukuthembeka kwesixhobo akwanelanga okanye ukuqina kwayo kuphantsi, kulula ukuhlangabezana neengxaki ezifana nokugqoka kwangaphambi kwexesha kunye nokudilika komphetho, okungachaphazeli nje kuphela umgangatho womatshini kodwa kukhokelela ekutshintsheni rhoqo izixhobo, ukwandisa ixesha lokunciphisa imveliso, kunye nokunciphisa ukusebenza kakuhle kwemveliso. Ke ngoko, ukukhetha izixhobo zesixhobo ezinokumelana nokunxiba kakuhle, ukuchasana nempembelelo, kunye nokuzinza kwe-thermal, kunye noyilo olufanelekileyo lwesakhiwo sesixhobo, sisitshixo sokuphucula ukuthembeka kwesixhobo kunye nokuqina.

(2) Ubungqongqo kunye namandla

Ukuhlangabezana neemfuno zobunzulu obukhulu bokusika kunye nokutya okukhawulezayo ngexesha lomatshini olukhuni, isixhobo kufuneka sibe nokuqina okuhle kunye namandla. Ubunzulu obukhulu bokusika kunye nokutya okukhawulezayo kunokubangela ukuba isixhobo simelane namandla amakhulu okusika. Ukuba ukuqina kwesixhobo akwanelanga, kuxhomekeke kwi-deformation, echaphazela ukuchaneka komatshini; Amandla angonelanga kunokukhokelela ekophukeni kwesixhobo kwaye kubangele iingozi zokhuseleko. Ngoko ke, kwinkqubo yoyilo lwesixhobo kunye nokuveliswa, amanyathelo afana nokuphucula imilo yejometri yesixhobo kunye nokukhetha izinto eziphezulu eziphezulu kufuneka zithathwe ukuze kuqinisekiswe ukuba isixhobo sinokuqina okwaneleyo kunye namandla.

(3) Ukuqhekeka kweChip kunye nokusebenza kokususa

Ukuphulwa kwe-chip kunye nokusebenza kakuhle kokususwa yimeko ebalulekileyo yokuqinisekisa ukusebenza okuqhelekileyo kwezixhobo zoomatshini. Kwinkqubo yeCNC milling, isizukulwana esiqhubekayo kunye nokuqokelela kweechips. Ukuba isixhobo asikwazi ukuphula ngokufanelekileyo kwaye sisuse iitshiphusi, siya kubangela ukuba iitshiphusi zibophe malunga nesixhobo okanye i-workpiece, echaphazela ukuzinza kwenkqubo yokusika kunye nokonakalisa isixhobo kunye nesixhobo somatshini. Ukuze ufezekise ukususwa kwe-chip elungileyo, iiparameters ze-cutting edge shape, i-angle yangaphambili, kunye ne-angle yangasemva yesixhobo kufuneka yenziwe ngokucophelela. Ngexesha elifanayo, ukhetho olufanelekileyo lweeparamitha zokusika kunye nokusetyenziswa kwe-cut fluid kunokunceda ukuphucula umphumo wokususwa kwe-chip.

(4) Ufakelo olulula kunye nohlengahlengiso

Ukulungelelaniswa kofakelo lwesixhobo kunye nohlengahlengiso kubaluleke kakhulu ekuphuculeni ukusebenza kakuhle kwemveliso kunye nokuqinisekisa ukuchaneka komatshini. Kwinkqubo yokucoca umatshini we-CNC, ngenxa yokutshintshwa kwesixhobo rhoqo kunye nohlengahlengiso lwendawo yesixhobo, ukuba ukufakwa kwesixhobo kunye nenkqubo yohlengahlengiso inzima kwaye inzima, iya kuchitha ixesha elininzi. Ngoko ke, izixhobo zokusika kunye nabaphathi bezixhobo ezinesakhiwo esilula, ukufakwa okuthembekileyo kunye nokubekwa, kunye nokulungelelaniswa okufanelekileyo kufuneka kukhethwe ukunciphisa ukutshintshwa kwesixhobo kunye nexesha lokulungelelanisa, kunye nokuphucula izinga lokusetyenziswa kwesixhobo somatshini.

(5) Izinto zesixhobo sokusika ezikumgangatho ophezulu

Ukukhetha izixhobo ezikumgangatho ophezulu sisiseko sokuphucula ukusebenza kwesixhobo. Okwangoku, izixhobo ezisetyenziswa ngokuqhelekileyo zeoomatshini bokusila be-CNCzibandakanya isinyithi esinesantya esiphezulu, ialloyi eqinileyo, iialloyi ezicatshuliweyo, iiseramikhi, i-cubic boron nitride, kunye nedayimane. Izixhobo ezahlukeneyo zesixhobo zineempawu ezahlukeneyo zokusebenza, kunye nezixhobo ezifanelekileyo zesixhobo kufuneka zikhethwe ngokusekelwe kwizinto ezifana nempahla yokusebenza, iteknoloji yokucubungula, kunye neemeko zokusika. Ngokomzekelo, izixhobo zokusika isinyithi esinesantya esiphezulu zinobunzima obuhle kunye nokusila, okwenza ukuba zilungele ukusetyenzwa kwamacandelo aqingqiweyo kunye nokusika okuphantsi kwesantya; Izixhobo zokusika i-alloy enzima zinobunzima obuphezulu kunye nokuchasana kakuhle kokunxiba, okwenza ukuba zilungele ukusika i-high-speed cut and rough Machining; Izixhobo zokusika ezigqunyiweyo ziphucula ngakumbi ukusebenza kwazo ngokugquma umphezulu wazo ngengubo enganyangekiyo kunye nobushushu obuphezulu obuphezulu, ezenza zilungele iimeko ezahlukeneyo zokusika.

2、 Ukuhlelwa kwezixhobo zomatshini wokugaya i-CNC

Kukho iintlobo ngeentlobo zeUmatshini wokungqusha we-CNCizixhobo, ezinokuhlelwa ngokweendidi ezahlukeneyo ngokwemigangatho yokwahlulahlula. Ezi zilandelayo ziindlela zokuhlela eziqhelekileyo:

(1) Ihlelwa ngokwesakhiwo sesixhobo

Izixhobo zokusika ezidibeneyo

Izixhobo zokusika ezidibeneyo zibhekisela kwizixhobo ezisebenzayo inxalenye yazo kunye ne-shank zenziwe ngokubanzi, ezifana ne-mill end, i-drills, njl. Ifanelekile ukucubungula iinxalenye ezinemilo elula kunye neemfuno ezichanekileyo ezichanekileyo.

Izixhobo zokusika ezifakwe ngaphakathi

Izixhobo zokusika ezifakelweyo zizixhobo ezifakela i-blade okanye amazinyo kumzimba wokusika, ezifana ne-inlaid end Mills, izixhobo zokuguqula, njl.

Uhlobo olukhethekileyo lwezixhobo zokusika

Izixhobo zokusika ezikhethekileyo zibhekisela kwizixhobo ezenzelwe ukuhlangabezana neemfuno ezithile ezikhethekileyo zokucwangcisa, ezifana nezixhobo zokwenza izixhobo, izixhobo ezidibeneyo, njl. Izixhobo zokusika ezihlanganisiweyo zinokugqiba amanyathelo okucubungula amaninzi kwinkqubo enye yokusika, njengokugaya kunye nokugaya izixhobo zokusika ezidibeneyo, izixhobo zokusika kunye ne-milling composite cutting, njl.

(2) Ukuhlelwa ngokwemathiriyeli yesixhobo

Izixhobo zokusika isinyithi esinesantya esiphezulu

Isantya esiphezulu sensimbi luhlobo lwensimbi ephezulu ye-alloy equlethe inani elibalulekileyo lezinto ezixubileyo ezifana ne-tungsten, i-chromium, kunye ne-vanadium. Izixhobo zokusika isinyithi esinesantya esiphezulu zinobunzima obuhle kunye nokugaya, kwaye ziyakwazi ukumelana nemithwalo yempembelelo enkulu. Ngokuqhelekileyo zisetyenziselwa ukucubungula iinxalenye ezinemilo enzima kunye neemfuno ezichanekileyo ezichanekileyo, ezifana ne-drills, iimpompo, i-milling cutters, njl. Ngokomsebenzi ohlukeneyo, izixhobo zokusika i-speed-speed steel zingahlulwa zibe yintsimbi ye-speed-speed-mergency kunye ne-high-performance high-speed steel.

I-Universal high-speed steel: Ubunzima bayo buvela kwi-62 ukuya kwi-69HRC, inokumelana nokunxiba okuthile, amandla aphezulu kunye nokuqina, kwaye isantya sokusika ngokuqhelekileyo asiphezulu kune-45 ukuya kwi-60m / min, engafanelekanga ukusika isantya esiphezulu.

Ukusebenza okuphezulu kwentsimbi yesantya esiphezulu: Inqanaba lentsimbi elinokumelana nokushisa okuphezulu kunye nokumelana nokunxiba okufunyenwe ngokunyusa umxholo wekhabhoni kunye ne-vanadium ngesiseko sentsimbi ephezulu. Ukusebenza okuphezulu kwensimbi enesantya esiphezulu kunobulukhuni obuhle obubomvu, kwaye isenako ukugcina ubulukhuni be-60HRC kwi-620-660 ℃. Ukuqina kwayo ngamaxesha angama-2-3.5 yentsimbi ye-speed-speed ngokubanzi. Ukusebenza okuphezulu kwentsimbi yesantya esiphezulu ngokuqhelekileyo kusetyenziselwa ukusetyenzwa nzima kumatshini wezinto ezifana ne-alloys ephezulu yokushisa kunye ne-titanium alloys.

Izixhobo zokusika i-alloy enzima

I-Hard alloy yenziwe ngenkqubo ye-metallurgy engumgubo kusetyenziswa ubulukhuni obuphezulu, i-high melting point metal carbides (efana ne-tungsten carbide, titanium carbide, njl.) umgubo kunye nezibophelelo (ezifana ne-cobalt, i-nickel, njl.). Izixhobo zokusika i-alloy enzima zineempawu zobunzima obuphezulu, ukuchasana kakuhle kokugqoka, kunye nokumelana nokushisa okuphezulu, kunye nesantya sokusika i-100-300m / min, ifanelekile ukusika i-high-speed and machining rough. Izixhobo zokusika i-alloy enzima zingahlelwa kwi-tungsten cobalt (YG), i-tungsten titanium cobalt (YT), kunye ne-tungsten titanium tantalum (niobium) cobalt (YW) ngokusekelwe ekubunjweni kwayo kunye nokusebenza.

I-Tungsten cobalt (YG) i-alloys enzima ye-YG inomxholo ophezulu we-cobalt kunye nokuqina okulungileyo, okwenza ukuba zilungele ukusetyenzwa kwezinto ezinqabileyo ezifana nentsimbi etyhidiweyo kunye neentsimbi ezingenayo i-ferrous.

I-tungsten titanium cobalt (YT) ii-alloys ezinzima ze-YT zinomxholo ophezulu we-titanium, ukuqina okulungileyo kunye nokumelana nokunxiba, kwaye zifanelekile ukusetyenzwa kweplastiki njengentsimbi.

I-tungsten titanium tantalum (i-niobium) i-cobalt (YW) i-alloy enzima: i-YW i-alloy enzima idibanisa iingenelo ze-YG kunye ne-YT i-alloys enzima, enobunzima obuphezulu, ukuxhathisa ukunxiba, ukumelana nobushushu, kunye nokuqina, ilungele ukusetyenzwa kwezinto ezahlukeneyo, ngakumbi kunzima umatshini wezinto ezifana nentsimbi engenasici kunye nentsimbi enganyangekiyo.

Izixhobo zokusika ezigqunywe

Izixhobo zokusika eziboshwe zifakwe ngoluhlu lwezinto ezinqabileyo zokugqoka kunye nokushisa okuphezulu, ezifana ne-TiC, i-TiN, i-Al2O3, njl., phezu kwe-alloy enzima okanye izixhobo zokusika insimbi. Izixhobo zokusika ezigqunyiweyo zinokuphucula kakhulu ubulukhuni bomphezulu, ukumelana nokunxiba, kunye nokumelana nobushushu kwezixhobo zokusika, kunye nokwandisa ubomi babo benkonzo. Izixhobo zokusika ezifakwe iingubo zifanelekile kwiimeko ezahlukeneyo zokusika, ngokukodwa ukusika okuphezulu kunye nokusika okomileyo.

Izixhobo zokusika iCeramic

Izixhobo zokusika i-Ceramic ikakhulu zenziwe ngezinto ze-ceramic ezifana ne-alumina (Al2O3) kunye ne-silicon nitride (i-Si3N4), ezifakwe kwi-sintered kumaqondo aphezulu. Izixhobo zokusika i-Ceramic zineenzuzo ezifana nobunzima obuphezulu, ukuxhathisa okulungileyo, ukuxhathisa ukushisa okuphezulu, kunye nokuzinza okulungileyo kweekhemikhali. Isantya sokusika sinokufikelela kwi-500-1000m / min, okwenza ukuba bafanelekele ukusika i-high-speed and machining ngokuchanekileyo. Nangona kunjalo, izixhobo zokusika i-ceramic zine-brittleness ephezulu kunye nokumelana nempembelelo embi. Xa uzisebenzisa, ingqalelo kufuneka ihlawulwe ekuphepheni imithwalo yempembelelo.

Cubic boron nitride izixhobo zokusika

I-Cubic boron nitride (CBN) yinto eyenziweyo eyenziweyo enzima kakhulu enobunzima besibini kuphela kwidayimane. Izixhobo zokusika i-Cubic boron nitride zineenzuzo ezinjengokuqina okuphezulu, ukumelana nokunxiba kakuhle, ukumelana nobushushu obuphezulu, kunye nokuzinza okuhle kweekhemikhali. Isantya sokusika sinokufikelela kwi-1000-2000 m / min, okwenza ukuba zilungele ukusika i-high-speed cutting and precision machining of high hardness materials ezifana nentsimbi ecinyiweyo kunye nentsimbi epholileyo.

Izixhobo zokusika idayimani

Idayimani yeyona nto inzima kwindalo, kwaye izixhobo zokusika idayimani zinobulukhuni obuphezulu kakhulu, ukuxhathisa ukunxiba, kunye ne-thermal conductivity. Isantya sokusika sinokufikelela kwi-2000-5000m / min, okwenza ukuba bafanelekele ukusika i-high-speed cutting and machining ngokuchanekileyo yezinto ezingenayo i-ferrous kunye ne-non-metallic. Nangona kunjalo, izixhobo zokusika idayimane zibiza kwaye azifanelekanga ukusetyenzwa kwezixhobo zetsimbi ezisekelwe kwintsimbi, njengoko iidayimani zifumana ukuphendulwa kweekhemikhali ngentsimbi kwiqondo lokushisa eliphezulu.

3, Ukukhethwa kwezixhobo zokusika izixhobo zoomatshini bokugaya i-CNC

Kukho iintlobo ngeentlobo zezixhobo zesixhobo ezisetyenziselwa umatshini we-CNC, nganye ineempawu zayo zokusebenza ezizodwa kunye nokusetyenziswa kwayo. Xa ukhetha izixhobo zesixhobo, kuyimfuneko ukuqwalasela ngokubanzi izinto ezifana nezixhobo zokusebenza, iteknoloji yokucubungula, iimeko zokusika, njl., Ukuze ukhethe izixhobo ezifanelekileyo kakhulu.

(1) Iimpawu zokusebenza zezixhobo zokusika izixhobo zokusika isinyithi

Isixhobo sokusika izixhobo zokusika isinyithi ngokuqhelekileyo kufuneka sibe noluhlu lwezalathisi zokusebenza, phakathi kwazo ukuqina, amandla, ubunzima obomvu, ukuqhutyelwa kwe-thermal, njl.

Ukuqina kukukwazi kwezixhobo zokuxhathisa ukunxiba, kwaye okukhona ukuqina kokuqina, kokukhona isixhobo siyaxhathisa. Amandla kukukwazi kwezixhobo zesixhobo ukuxhathisa ukuphuka kunye nokuguqulwa, kunye nezixhobo ezinamandla eziphezulu zinokumelana namandla amakhulu okusika. Ubunzima obubomvu bubhekisela kwikhono lezixhobo zesixhobo sokugcina ubunzima kwiqondo lokushisa eliphezulu, kunye nezixhobo ezinobunzima obuhle obomvu zifanelekile ukusika isantya esiphezulu. I-Thermal conductivity ichaphazela umphumo wokutshatyalaliswa kobushushu bezixhobo zokusika. Izixhobo ezine-conductivity efanelekileyo ye-thermal zinokudlulisela ngokukhawuleza ukushisa kokusika kunye nokunciphisa ukutshitshiswa kwe-thermal kwezixhobo.

(2) Isixhobo esifanelekileyo

Isixhobo esifanelekileyo sesixhobo kufuneka sibe nobulukhuni kunye namandla, kunye nobunzima obuhle obubomvu, ukuhanjiswa kwe-thermal, ukumelana nokunxiba, kunye nokuqina. Nangona kunjalo, kwizicelo ezisebenzayo, kunzima ukufumana isixhobo sesixhobo esihlangabezana ngokupheleleyo nazo zonke iimfuno, ngoko ke kuyimfuneko ukulinganisa kwaye ukhethe ngokwemiqathango ethile yokucubungula.

(3) Izinto ezisetyenziswa ngokuqhelekileyo izixhobo zokusika kwizicelo eziphathekayo

Kwinkqubo ebonakalayo, izixhobo zokusika i-alloy eqinileyo kunye ne-coated hard alloy zisetyenziswa kakhulu ngenxa yokusebenza kwazo okugqwesileyo.

Izixhobo zokusika i-alloy enzima zinobunzima obuphezulu kunye nokuxhatshazwa kokugqoka, ezinokuziqhelanisa neemfuno zokusika i-high-speed cut and rough machining. Izixhobo zokusika ezifakwe kwi-alloy enzima, ngesiseko sezixhobo zokusika i-alloy enzima, ziphucula ngakumbi ukusebenza kwazo kwaye zandise ubomi babo benkonzo ngokuzigquma ngomqolo wokugquma kunye nobushushu obuphezulu obunganyangekiyo.

Kwezinye izinto ezinzima zomatshini, ezifana ne-alloys ephezulu yokushisa, i-titanium alloys, njl., izixhobo zokusika ze-cubic boron nitride kunye nezixhobo zokusika idayimani zineenzuzo ezizodwa. Izixhobo zokusika i-cubic boron nitride zinobunzima obuphezulu kunye nobunzima obuhle obubomvu, obunokuthi bunqumle ngokufanelekileyo izinto ezinzima; Izixhobo zokusika idayimani zinobulukhuni obuphezulu kakhulu kunye ne-thermal conductivity, ezenza zilungele ukuchaneka kwe-machining yezinto ezingenayo i-ferrous kunye ne-metallic.

Nangona izixhobo zokusika isinyithi esinesantya esiphezulu azikho nzima kwaye zinxiba-zixhathise njengezixhobo zokusika i-alloy enzima, zisenezicelo ezithile ekusetyenzweni kweengxenye ezibunjiweyo ezintsonkothileyo kunye nokusika okuncinci ngenxa yokuqina kwazo okuhle kunye nokusila.

Izixhobo zokusika i-Ceramic zinobunzima obuphezulu kunye nokuchasana kakuhle kokugqoka, kodwa zi-brittle kwaye zifanelekile ukusika i-high-speed and machining ngokuchanekileyo.

4, Imiba enempembelelo yokukhethwa kwesixhobo koomatshini bokungqusha be-CNC

Xa ukhetha izixhobo zomatshini wokungqusha we-CNC, le miba ilandelayo kufuneka iqwalaselwe ngokubanzi:

(1) Ukusebenza kwesixhobo somatshini

Iindidi ezahlukeneyo kunye neenkcukacha zoomatshini bokugaya i-CNC baneempawu ezahlukeneyo zokusebenza, ezifana nesantya se-spindle, izinga lokutya, amandla, i-torque, njl. Ngokomzekelo, kumatshini wokugaya i-high-speed-speed, izixhobo zokusika ezifanelekileyo zokusika i-high-speed cutting kufuneka zikhethwe, ezifana ne-coated hard alloy tools, izixhobo ze-ceramic, njl. Kumatshini wokugaya amandla aphezulu, izixhobo zokusika ezinamandla aphezulu kunye nokuqina kunokukhethwa, njengezixhobo ezidibeneyo zokusika i-alloy.

(2) Isixhobo sokusebenza

Ukusebenza kwezixhobo zokusebenza kunempembelelo enkulu ekukhethweni kwesixhobo. Izinto ezahlukeneyo zokusebenza zinobunzima obuhlukeneyo, amandla, ukuqina, ukuhanjiswa kwe-thermal, njl. Xa kusetyenzwa izinto zeplastiki ezifana nentsimbi, kuyacetyiswa ukuba ukhethe uhlobo lwe-YT izixhobo zokusika i-alloy enzima okanye izixhobo zokusika ezifakwe; Xa kusetyenzwa nzima kumatshini izixhobo ezifana ne-alloys ephezulu yobushushu kunye ne-titanium alloys, izixhobo zokusika ze-cubic boron nitride okanye izixhobo zokusika idayimane kufuneka zikhethwe.

(3) Inkqubo yokuqhuba

Uhlobo lwenkqubo ye-machining (njenge-machining rough, i-semi precision machining, i-precision machining) kunye neeparitha zokusika (ezifana nesantya sokusika, izinga lokutya, ukusika ubunzulu) nazo zichaphazela ukukhethwa kwezixhobo zokusika. Xa umatshini wokusika, izixhobo zokusika ezinamandla aphezulu kunye nokuqina okunokumelana namandla amakhulu okusika kufuneka kukhethwe, njengezixhobo eziqinileyo zokusika i-alloy; Xa kulungiswa ngokuchanekileyo, izixhobo ezinomgangatho ophezulu kunye nomgangatho ophezulu womgangatho kufuneka zikhethwe, ezifana nezixhobo ezifakwe i-alloy enzima okanye izixhobo ze-ceramic.

(4) Ukusika imali

Ubungakanani bexabiso lokusika linquma ngokuthe ngqo amandla okusika kunye nokusika ukushisa okubangelwa sisixhobo. Xa umatshini kunye nexabiso elikhulu lokusika, izixhobo zokusika ezinamandla aphezulu kunye nokumelana nokushisa okulungileyo kufuneka kukhethwe; Xa umatshini kunye namanani amancinci okusika, izixhobo zokusika ezinobunzima obuphezulu kunye nokumelana nokugqoka kakuhle kunokukhethwa.

5, Amanyathelo kunye neendlela zokukhetha izixhobo zokusika kumatshini wokusila we-CNC

Xa ukhetha izixhobo zomatshini wokungqusha we-CNC, la manyathelo alandelayo angalandelwa:

(1) Qinisekisa iimfuno zokusetyenzwa

Okokuqala, kuyafuneka ukucacisa imilo, ubungakanani, iimfuno ezichanekileyo, iimfuno zomgangatho womphezulu, kunye neendlela zokusetyenzwa (ezifana nomatshini orhabaxa, umatshini wokuchaneka, kunye nomatshini ochanekileyo) weendawo ezisetyenzisiweyo.

(2) Hlalutya imathiriyeli yesixhobo somsebenzi

Hlalutya ukusebenza kwezinto zokusebenza, kubandakanywa ubulukhuni, amandla, ukuqina, ukuqhutyelwa kwe-thermal, njl., ukumisela izixhobo ezifanelekileyo zesixhobo.

(3) Khetha uhlobo lwesixhobo

Ngokweemfuno zokusetyenzwa kunye nezixhobo zokusebenza, khetha uhlobo olufanelekileyo lwesixhobo, njengeemillmill, i-drills, i-boring cutters, njl.

(4) Khangela iiparamitha zesixhobo

Gqiba ububanzi, ubude, inani lamaphethelo, i-angle ye-helix, i-angle ehamba phambili, i-angle yokulandela, kunye nezinye iiparitha zesixhobo sokusika ngokusekelwe kwiiparitha zokusika kunye nokusebenza komatshini.

(5) Khetha izixhobo zokusika izixhobo kunye nababoneleli

Emva kokumisela uhlobo kunye neeparitha zezixhobo zokusika, khetha iimpawu eziyaziwayo kunye nabanikezeli abathembekileyo ukuqinisekisa umgangatho wezixhobo kunye nenkonzo emva kokuthengisa.

6, Ukusetyenziswa kunye nokugcinwa kwezixhobo zomatshini wokugaya i-CNC

Ukukhetha isixhobo esifanelekileyo linyathelo nje lokuqala, kwaye ukusetyenziswa ngokufanelekileyo kunye nokugcinwa kwesixhobo kubalulekile ngokulinganayo ekuqinisekiseni umgangatho womatshini kunye nokwandisa ubomi besixhobo.

(1) Ukufakwa kwezixhobo zokusika

Xa ufaka isixhobo, kubalulekile ukuqinisekisa ukuchaneka kokulungelelaniswa phakathi kwesixhobo kunye nomphathi wesixhobo, ukuqinisekisa ukuba isixhobo sifakwe ngokuqinileyo nangokuchanekileyo. Ngelo xesha, ingqalelo kufuneka ihlawulwe kwisalathiso sofakelo kunye nesikhundla sezixhobo ukuphepha iimpazamo zokufakela ezinokubangela iimpazamo zomatshini okanye umonakalo wesixhobo.

(2) Ukukhethwa kweeparamitha zokusika izixhobo zokusika

Ukukhethwa okufanelekileyo kweeparamitha zokusika ngundoqo ekuqinisekiseni ukusika okuqhelekileyo kunye nokwandisa ubomi besixhobo. Iiparamitha zokusika ziquka isantya sokusika, izinga lokutya, ubunzulu bokusika, njl., kwaye kufuneka ziqwalaselwe ngokubanzi ngokusekelwe kwizinto ezifana nezixhobo zesixhobo, izinto zokusebenza, kunye nenkqubo yomatshini. Ngokuqhelekileyo, ngaphakathi koluhlu oluvumelekileyo lwezixhobo zokusika, isantya esiphezulu sokusika kunye namazinga amancinci okutya kufuneka kukhethwe ukuphucula ukusebenza kakuhle komatshini kunye nomgangatho ophezulu.

(3) Ukupholisa kunye nokuthambisa izixhobo zokusika

Ngexesha lenkqubo yokusika, iindlela ezifanelekileyo zokupholisa kunye nokuthambisa kufuneka zisetyenziswe ukunciphisa ubushushu bokusika, ukunciphisa ukunxiba kwesixhobo, kunye nokuphucula umgangatho womgangatho owenziwe ngoomatshini. Iindlela eziqhelekileyo zokupholisa kunye nokuthambisa ziquka ukusika ukupholisa kwamanzi, ukupholisa umoya, ukuthambisa inkungu yeoyile, njl.

(4) Ukugcinwa kunye nokugcinwa kwezixhobo zokusika

Emva kokucubungula, ii-chips kunye neoli ye-oyile kwizixhobo zokusika kufuneka zihlanjululwe ngexesha elifanelekileyo, kwaye ukugqoka izixhobo kufuneka kuhlolwe. Ukuba kukho nayiphi na into enxibayo, kufuneka ilolwe okanye itshintshwe ngexesha elifanelekileyo. Ngexesha elifanayo, ukugcinwa rhoqo kufuneka kuqhutywe kwizixhobo zokusika, ezifana nokusebenzisa ioli ye-rust proof, ukujonga ukuchaneka kwesixhobo sokuphatha, njl., Ukuqinisekisa ukusebenza kunye nobomi benkonzo yezixhobo zokusika.

7. Isiphelo

Ukukhethwa kwezixhobo zokusika kumatshini wokugaya i-CNC ngumsebenzi onzima kunye nobalulekileyo ofuna ukuqwalaselwa ngokubanzi kwizinto ezininzi ezifana nokusebenza komatshini, izixhobo zokusebenza, iinkqubo zomatshini, kunye nezixa zokusika. Ukukhetha kunye nokusebenzisa izixhobo zokusika ngokuchanekileyo akunakuphucula kuphela umgangatho womatshini kunye nokusebenza kakuhle kwemveliso, kodwa nokunciphisa iindleko zokuvelisa kunye nokwandisa ubomi benkonzo yezixhobo zoomatshini. Ngoko ke, kwimveliso yangempela, isixhobo esifanelekileyo kufuneka sikhethwe ngokusekelwe kwimeko ethile yokucubungula kunye neempawu zokusebenza kwesixhobo, kwaye ukusetyenziswa kunye nokulawulwa kokugcinwa kwesixhobo kufuneka kuqiniswe ukuze kuxhaswe ngokupheleleyo iingenelo zoomatshini bokugaya i-CNC kunye nokubonelela ngenkxaso eqinile kuphuhliso loshishino lokuvelisa.