Kwimveliso yanamhlanje,Umatshini wokungqusha we-CNCukwisikhundla esibalulekileyo. Ukuze kuqinisekiswe ukusebenza kwayo okuzinzile kunye nokusebenza kakuhle kwexesha elide, ukugcinwa okuchanekileyo kubaluleke kakhulu. Makhe sixoxe ngendlela yokugcina umatshini wokugaya we-CNC ngobunzulu kunye neUmatshini wokungqusha we-CNCumenzi.

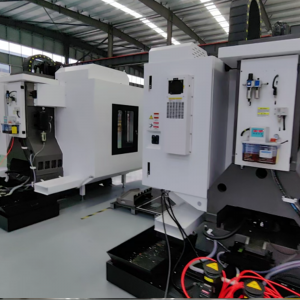

I. Ukugcinwa kwenkqubo yolawulo lwamanani

Inkqubo ye-CNC yinxalenye engundoqo yeUmatshini wokungqusha we-CNC, kunye nokugcinwa ngokucophelela kuyisitshixo sokuqinisekisa ukusebenza okuqhelekileyo kwesixhobo somatshini.

Sebenza ngokungqongqo ngokuhambelana neenkcukacha zokusebenza kwenkqubo yolawulo lwamanani ukuqinisekisa ukuqaliswa okuchanekileyo, ukusebenza kunye neenkqubo zokuvala. Ukuqhelana kunye nokulandela iimfuno zenkqubo yokutshatyalaliswa kobushushu kunye nenkqubo yokuphuma komoya yekhabhinethi yombane, qinisekisa indawo efanelekileyo yokutshatyalaliswa kobushushu kwikhabhinethi yombane, kunye nokuthintela ukusilela kwenkqubo okubangelwa kukufudumala.

Kwizixhobo zegalelo kunye nemveliso, kufuneka zigcinwe rhoqo. Khangela ukuba umgca wokudibanisa ukhululekile kwaye i-interface iyinto eqhelekileyo ukuqinisekisa ukuchaneka kunye nokuzinza kokuhanjiswa kwedatha.

Ukunxitywa kunye nokukrazula kwebrashi yemoto yeDC kufuneka kuqwalaselwe. Ukutshintsha kokunxiba kwebrashi kuya kuchaphazela ukusebenza kwemoto kwaye kunokubangela nomonakalo wemoto. Ngoko ke, ibrashi yombane kufuneka ihlolwe rhoqo kwaye ithathelwe indawo ngexesha. Kwiilathe zeCNC,oomatshini bokusila be-CNC, amaziko omatshini kunye nezinye izixhobo, kucetyiswa ukuba kwenziwe uhlolo olubanzi kanye ngonyaka.

Kwiibhodi zesekethe eziprintiweyo zexesha elide kunye neebhodi zesekethe zokugcinwa kwebhetri, kufuneka zitshintshwe rhoqo. Yifake kwinkqubo ye-CNC ixesha elide ukukhusela umonakalo obangelwa ukungasebenzi kwexesha elide.

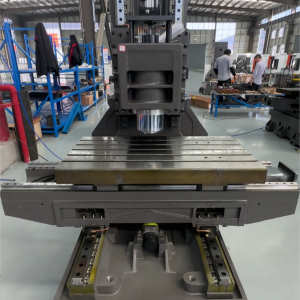

II. Ukugcinwa kwamalungu oomatshini

Ukugcinwa kwebhanti ye-spindle drive ayinakungahoywa. Lungiselela rhoqo ukuqina kwebhanti ukuthintela ukutyibilika kwebhanti. I-Skidding ayiyi kuchaphazela kuphela ukuchaneka kokucubungula, kodwa kukhokelela ekungaphumeleli kwezixhobo.

Hlola ngononophelo itanki yobushushu egudileyo ye-spindle. Lungisa iqondo lobushushu, qinisekisa ukuba ubushushu beoyile buphakathi koluhlu olufanelekileyo, gcwalisa ioyile ngexesha, kwaye uhlambe isihluzo rhoqo ukuze uqinisekise ukucoceka kunye nefuthe lokuthambisa ioyile.

Emva kokusetyenziswa kwexesha elideUmatshini wokungqusha we-CNC, kusenokubakho iingxaki ngesixhobo sokugoqa sokusonta. Umzekelo, kunokubakho izikhewu, eziya kuchaphazela isixhobo esibambekayo. Ukufuduswa kwepiston ye-hydraulic cylinder kufuneka kuhlengahlengiswe kwangexesha ukuze kuqinisekiswe ukuba i-clamping yesixhobo iqinile kwaye inokwethenjelwa.

Jonga rhoqo imeko yeperi yebhola Screw. Lungisa isithuba se-axial sesibini esinemisonto ukuqinisekisa ukuchaneka kokudluliselwa okubuyela umva kunye nokuqina kwe-axial. Ngexesha elifanayo, khangela ukuba uxhulumaniso phakathi kwe-screw kunye nebhedi lukhululekile, kwaye lugxininise ngexesha xa lufunyenwe lukhululekile. Ukuba isixhobo sokukhusela intambo sonakalisiwe, kufuneka sitshintshwe ngokukhawuleza ukukhusela uthuli okanye iitshiphusi ukuba zingangeni, zibangele umonakalo we-screw.

III. Ukugcinwa kwe-hydraulic kunye ne-pneumatic systems

Gcina rhoqo i-hydraulic kunye ne-pneumatic systems. Geza okanye ubeke indawo yokucoca okanye ukucoca ukuqinisekisa ukucocwa kwemithombo yeoli kunye negesi kwiinkqubo ze-hydraulic kunye ne-pneumatic.

Jonga rhoqo umgangatho weoli ye-hydraulic kunye nesimo sokusebenza kwenkqubo yoxinzelelo. Guqula ioli ye-hydraulic ngexesha ngokweemfuno zokuqinisekisa ukusebenza okuqhelekileyo kwenkqubo ye-hydraulic.

Gcina rhoqo isihluzo somoya ukukhusela ukungcola emoyeni ekungeneni kwi-pneumatic system. Ngexesha elifanayo, ukuchaneka komatshini kufuneka kuhlolwe rhoqo, kwaye kulungiswe kwaye kulungiswe ngexesha lokuqinisekisa ukuba ukuchaneka kokucubungula kuhlala kugcinwa kwinqanaba eliphezulu.

IV. Ugcino kweminye imiba

Imbonakalo yeUmatshini wokungqusha we-CNCkufuneka kwakhona icocwe rhoqo. Susa uthuli, ioli kunye nobutyobo kumphezulu kwaye ugcine izixhobo zomatshini zicocekile. Oku akukona nje ukuhambelana ne-aesthetics, kodwa kuthintela uthuli kunye nezinye izinto ezingcolileyo ekungeneni kwisixhobo somatshini, ezichaphazela ukusebenza kwezixhobo.

Jonga rhoqo ukuba isixhobo sokukhusela isixhobo somatshini sichanekile. Isixhobo sokukhusela sinokukhusela ngokufanelekileyo umqhubi kunye nesixhobo somatshini kwingozi yengozi kunye nomonakalo, kwaye kufuneka kuqinisekiswe ukusebenza kwayo okuqhelekileyo.

Iireyili zesikhokelo, izikrufu kunye nezinye izinto eziphambili zeUmatshini wokungqusha we-CNCkufuneka ithanjiswe rhoqo. Khetha i-lubricant efanelekileyo kwaye uyifake okanye uyifake ngokwexesha elimiselweyo kunye nendlela yokunciphisa ukunxiba kunye nokwandisa ubomi benkonzo yenxalenye.

Nika ingqalelo kubume obungqonge isixhobo somatshini. Kuphephe ukusebenzisa izixhobo zoomatshini kwindawo efumileyo, yobushushu obuphezulu, enothuli nakwezinye iindawo ezirhabaxa, kwaye uzame ukwenza indawo elungileyo yokusebenza yezixhobo zoomatshini.

Uqeqesho lwabasebenzi nalo lubalulekile. Qinisekisa ukuba umqhubi uqhelene nokusebenza, indlela yokusebenza kunye neemfuno zokugcinwa kwesixhobo somatshini, kwaye asebenze ngokuhambelana nemigaqo yokusebenza. Kuphela ngokudibanisa ukusebenza okuchanekileyo kunye nokugcinwa ngononophelo kunokusebenza ngokufanelekileyooomatshini bokusila be-CNCzifakwe kumdlalo opheleleyo.

Ukuseka inkqubo yokugcinwa kwerekhodi egqibeleleyo. Rekhoda umxholo, ixesha kunye nabasebenzi bolondolozo kunye nolunye ulwazi lwesondlo ngasinye ngokweenkcukacha ukuze kulandelelwe kwaye kuhlalutywe. Ngokuhlalutya iirekhodi zokugcinwa, iingxaki kunye neengozi ezifihliweyo zezixhobo zoomatshini zinokufumaneka ngexesha, kwaye amanyathelo ajoliswe kuwo anokuthathwa ukuze azisombulule.

Kwezinye iindawo zokunxiba kunye nezinto ezisetyenziswayo, iinxalenye ezifanelekileyo ezifanelekileyo kufuneka zilungiswe kwangaphambili. Ngale ndlela, inokuthi iqhutywe ngexesha xa kufuneka litshintshwe, ukwenzela ukuba ugweme ukuchithwa kwesixhobo somatshini ngenxa yokungabikho kweendawo ezinqabileyo kunye nokuchaphazela inkqubela phambili yokuvelisa.

Mema rhoqo abasebenzi abaqeqeshiweyo bolondolozo ukuba benze uhlolo olubanzi kunye nokugcinwa kwezixhobo zoomatshini. Banolwazi oluthe chatha lobuchwephesha kunye nezakhono zokufumana ezinye iingxaki ezinokubakho kwaye bacebise izisombululo ezifanelekileyo.

Yomeleza ukuhlolwa kwemihla ngemihla kwezixhobo zoomatshini. Kumsebenzi wemihla ngemihla, abaqhubi kufuneka bahlale benikela ingqalelo kwimeko yokusebenza kwesixhobo somatshini, kwaye bayeke kwaye bajonge ngexesha ukuba bafumana iimeko ezingaqhelekanga, ukuze baphephe iingxaki ezincinci ezijike zibe ziintsilelo ezinkulu.

Gcina unxibelelwano olusondeleyoUmatshini wokungqusha we-CNCabavelisi. Gcina unolwazi lwetekhnoloji yamva nje kunye neendlela zokugcinwa kwezixhobo zoomatshini, kwaye ufumane inkxaso yobugcisa kunye nenkonzo yokuthengisa emva kokuthengisa kubenzi. Xa uhlangabezana neengxaki ezinzima, unokubonisana nomenzi ngexesha loncedo lwengcali.

Ngelizwi, ukugcinwa kweUmatshini wokungqusha we-CNCngumsebenzi ocwangcisiweyo nonobuchule, ekufuneka uqalwe kwimiba emininzi. Kuphela ngamanyathelo okulolonga ajikeleza yonke indawo apho sinokuthi siqinisekise ukubaUmatshini wokungqusha we-CNCihlala igcina ukusebenza kakuhle kunye nemeko yokusebenza, idala ixabiso elikhulu kwishishini. Kwangaxeshanye, amashishini kufuneka abethelele ukubaluleka okukhulu kugcino lweoomatshini bokusila be-CNC, qulunqa izicwangciso zenzululwazi nezifanelekileyo, kwaye ulandele ngokungqongqo isicwangciso. Abanini-zithuthi kunye nabasebenzi bolondolozo kufuneka ngalo lonke ixesha bephucula umgangatho wabo kunye nenqanaba lezakhono, benze ngononophelo uxanduva lolondolozo, kwaye babonelele ngesiqinisekiso esiqinileyo sokusebenza kwexesha elide kunye nozinzooomatshini bokusila be-CNC. Kwixesha elizayo imveliso yoshishino,oomatshini bokusila be-CNCiya kuqhubeka idlala indima ebalulekileyo, kwaye ukulungiswa okuchanekileyo kuya kuba ngundoqo ekuqinisekiseni ukusebenza kwayo ngokufanelekileyo. Masisebenze kunye ukwenza umsebenzi olungileyo ekugcinweni kweoomatshini bokusila be-CNCkunye nokukhuthaza uphuhliso oluqhubekayo kunye nenkqubela phambili yemveliso yemizi-mveliso.

Kweyona nkqubo yolondolozo, sikwafuna ukuhoya ezi ngongoma zilandelayo:

Ukhuseleko kuqala. Xa siqhuba nawuphi na umsebenzi wokulungisa, kufuneka sithobele ngokungqongqo iinkqubo zokusebenza zokhuseleko ukuqinisekisa ukhuseleko lomntu lwabaqhubi.

Lumka kwaye ube nomonde. Umsebenzi wokulungisa kufuneka ube ngocokisekileyo, ungabi nabubudenge obuncinane. Yiba nesazela kwaye ube noxanduva lokuhlola kunye nokugcinwa kwenxalenye nganye ukuqinisekisa ukuba akukho ngozi efihliweyo igcinwa.

Qhubeka ufunda. Ngophuhliso oluqhubekayo kunye nohlaziyo lweteknoloji, iindlela zokugcina zeoomatshini bokusila be-CNCnazo zihlala zitshintsha. Abasebenzi bezogcino kufuneka baqhubeke nokufunda kwaye rhoqo behlaziya ulwazi nezakhono zabo ukuhlangabezana neemfuno ezintsha zolondolozo.

Intsebenziswano. Ugcino lusoloko lufuna intatho-nxaxheba edibeneyo kunye nentsebenziswano yamasebe amaninzi kunye nabasebenzi. Kuyimfuneko ukuqinisa unxibelelwano kunye nokulungelelanisa, ukwenza umsebenzi odibeneyo, kunye nokuqinisekisa inkqubela phambili yomsebenzi wokulondoloza.

Ulawulo lweendleko. Xa sisenza umsebenzi wokulungisa, kufuneka silungiselele ngokufanelekileyo izibonelelo kunye nokulawula iindleko. Kuyimfuneko ukuba ungaqinisekanga kuphela umphumo wokulondoloza, kodwa kwakhona ugweme inkunkuma engadingekile.

Ukuqonda ngokusingqongileyo. Kwinkqubo yokugcinwa, kufuneka sinikele ingqalelo ekukhuselweni kwendalo, ukulahla ngokufanelekileyo i-oyile yenkunkuma, iinxalenye, njl., kwaye sinciphise ukungcoliseka kwendalo.

Ngokusebenzisa la manyathelo okugcina abanzi kunye nemigqaliselo, sinokuqinisekisa ngcono ukusebenza okuqhelekileyo kunye nobomi benkonzooomatshini bokusila be-CNC, kunye nokudala iinzuzo ezongezelelekileyo kwezoqoqosho nezentlalo kumashishini. Masisebenze kunye ukukhuthaza uphuculo oluqhubekayo nophuhliso logcino lweoomatshini bokusila be-CNCkunye nokwenza igalelo kuphuculo lwemizi-mveliso.

Ukongeza, sinokwamkela ezi ndlela zilandelayo zokulungisa ezintsha kunye nobuchwepheshe:

Inkqubo yogcino olukrelekrele. Ukusebenzisa abenzi boluvo abaphambili kunye netekhnoloji yokubeka iliso, imeko yokusebenza kunye neeparamitha zeUmatshini wokungqusha we-CNCzijongwa ngexesha lokwenyani, kwaye iingxaki zifunyanwa ngexesha kwaye izilumkiso zakwangoko zikhutshwa. Kwangaxeshanye, ngohlalutyo lwedatha kunye ne-algorithms ekrelekrele, ibonelela ngesiseko sokwenza izigqibo zenzululwazi ngomsebenzi wolondolozo.

Inkonzo yokugcinwa kude. Ngoncedo lwe-Intanethi kunye nethekhnoloji yonxibelelwano olude, unxibelelwano olukude phakathiUmatshini wokungqusha we-CNCabavelisi kunye nabasebenzisi bayaqondwa. Abavelisi banokubeka iliso kude kwaye baxilonge izixhobo zoomatshini, kwaye banike isikhokelo sokugcinwa kude kunye nenkxaso yobugcisa.

Ugcino oluqikelelweyo. Ngokuhlalutya idatha yembali kunye nesimo sokusebenza kweisixhobo somatshini, baqikelele iimpazamo neengxaki ezinokwenzeka, kwaye bathathe amanyathelo okuthintela nokugcina kwangaphambili ukuphepha ukwenzeka kokusilela.

Iteknoloji yokugcina eluhlaza. Sebenzisa izithambisi ezihambelana nokusingqongileyo, izicoci kunye nezinye izinto zokulungisa ukunciphisa ukungcoliseka kwendalo. Kwangaxeshanye, hlola iindlela zokugcina ukonga amandla ukunciphisa ukusetyenziswa kwamandla kwezixhobo zoomatshini.

Ukusetyenziswa kobuchwephesha boshicilelo be-3D ekuveliseni iindawo ezisecaleni. Kwezinye iindawo ezisecaleni ekunzima ukuzithenga, itekhnoloji yoshicilelo ye-3D ingasetyenziselwa ukwenza, ukunciphisa umjikelo wokubonelela ngezinto ezisecaleni, kunye nokuphucula ukusebenza kakuhle.

Uhlalutyo lwedatha enkulu kunye nezigqibo zokugcinwa. Ukuqokelela kunye nokulungelelanisa inani elikhulu ledatha yokugcina isixhobo somatshini, uphonononge ixabiso elinokubakho ledatha ngokusebenzisa iteknoloji enkulu yokuhlalutya idatha, kwaye unikeze isiseko sokuqulunqa izicwangciso zesayensi kunye nengqiqo yokugcina kunye nezicwangciso.

Ezi ndlela zintsha zogcino kunye nobuchwepheshe ziya kuzisa amathuba amatsha kunye nemingeni kugcino lweoomatshini bokusila be-CNC. Amashishini kunye namasebe afanelekileyo kufuneka aphonononge ngenkuthalo kwaye asebenzise obu buchwepheshe butsha ukuphucula ngokuqhubekayo inqanaba logcino kunye nomgangatho we.oomatshini bokusila be-CNC.

Ngelizwi, ukugcinwa kweoomatshini bokusila be-CNCngumsebenzi wexesha elide nonzima, ofuna iinzame zethu ezizingileyo kunye nokusungula izinto ezintsha. Ngokusebenzisa amanyathelo olondolozo lwesayensi kunye nengqiqo, iindlela zobugcisa eziphambili kunye neemfuno zolawulo olungqongqo, siya kuba nako ukuqinisekisa ukusebenza ixesha elide oluzinzileyo kunye nokusebenza ngokufanelekileyooomatshini bokusila be-CNCkunye nokwenza igalelo elikhulu kuphuhliso lwamashishini kunye nenkqubela phambili yoluntu. Masisebenze kunye ukudala ikamva lemizi-mveliso elingcono!

Millingmachine@tajane.comLe yidilesi yam yemeyile. Ukuba uyayifuna, ungandithumelela i-imeyile. Ndilinde ileta yakho eseTshayina.