Iziko lomatshini le-CNC: undoqo weteknoloji yokuvelisa

I. Intshayelelo

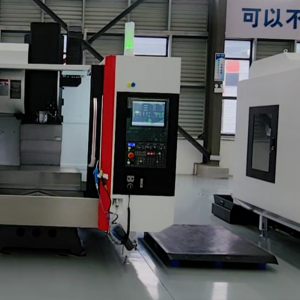

Kwishishini lemveliso yanamhlanje,Iziko lomatshini le-CNC, njengesixhobo esingundoqo somatshini we-CNC, idlala indima ebalulekileyo. Idibanisa itekhnoloji ephezulu kunye nemisebenzi ukufezekisa ukusebenza ngokufanelekileyo kunye nokuchanekileyo kunye nokubonelela ngeengxenye eziphezulu kunye neemveliso kumashishini ahlukeneyo. Eli nqaku liza kuxubusha nzulu iimpawu, imigaqo processing, iingenelo kunye nokusilelaamaziko Machining CNC, kwaye bahlalutye isicelo sabo kunye nophuhliso lwexesha elizayo kwishishini lokuvelisa.

II. Iimpawu zeCNC Machining Centre

Iziko lomatshini le-CNC liphuhliswa ngokwesiseko seoomatshini bokusila be-CNC, kodwa ineempawu ezizodwa eziyahlula kumatshini wokungqusha we-CNC. Enye yezona zinto zibalulekileyo kwilayibrari yayo yeemela kunye nokukwazi ukubuyisela ngokuzenzekelayo iimela. Ngesi sixhobo sokutshintsha isixhobo esizenzekelayo, iziko lomatshini linokutshintsha izixhobo ezahlukeneyo ezahlukeneyo kwi-clamping enye, ukuze kugqitywe imisebenzi eyahlukeneyo yomatshini enzima. Eli nqaku liphucula kakhulu ukusebenza kakuhle kunye nokuguquguquka, linciphisa inani lokubethelwa kwezinto zokusebenza, kwaye linciphisa ukubakho kweempazamo zomatshini.

Ukongeza, amaziko omatshini e-CNC ahlala exhotyiswe ngeenkqubo zokulawula ezichanekileyo kunye nobuchwepheshe obuphambili bokuqhuba, obunokuqinisekisa ukuchaneka kunye nokuzinza komatshini. Iyakwazi ukucubungula izixhobo zokusebenza zeemilo ezahlukeneyo kunye nobukhulu, nokuba yijometri elula okanye umphezulu onzima, onokujongana nawo ngokulula. Kwangaxeshanye, iziko lomatshini linamandla okusika olomeleleyo kunye nokusebenza kwesantya esiphezulu, esinokuhlangabezana neemfuno zamashishini ahlukeneyo okusebenza kakuhle kunye nomgangatho.

III. Imigaqo yokumiselwa kweendlela zokulungisa

Kwinkqubo yeziko lomatshini le-CNC, kubaluleke kakhulu ukumisela ngokufanelekileyo indlela yokucubungula. Oku kulandelayo yimigaqo elandelwa ngokubanzi:

1. Ukuqinisekisa ukuchaneka kunye noburhabaxa bomphezulu we-workpiece: Uyilo lwendlela yomatshini kufuneka kuqala iqwalasele indlela yokuqinisekisa ukuchaneka kunye neemfuno zobunzima bomphezulu womsebenzi ocutshungulweyo. Oku kufuna uqwalaselo olubanzi lwezinto ezifana nokukhethwa kwesixhobo, ukusetwa kweparamitha yokusika kunye nolandelelwano lomatshini. Ngokucwangciswa okufanelekileyo, iimpazamo zokucubungula zinokuncitshiswa kwaye umgangatho wemisebenzi ungaphuculwa.

2. Ukunciphisa indlela yokucubungula: Ukuze kuphuculwe ukusebenza kakuhle, indlela yokucubungula kufuneka icuthwe kangangoko kwaye ixesha lokuhamba elingenanto kufuneka lincitshiswe. Oku kunokufezekiswa ngokulungiselela indlela yesixhobo kunye nokulungelelanisa ngokufanelekileyo inkqubo yokucubungula. Kwangaxeshanye, kunqande ukusetyenzwa ngokuphindaphindiweyo okungafunekiyo kunye neendlela ezijikelezayo ukugcina ixesha lokucubungula kunye namandla.

3. Ubalo lwamanani olwenziwe lula: Ukumiselwa kwendlela yokucubungula kufuneka kube lula umthwalo womsebenzi wokubala amanani kangangoko kunokwenzeka ukulungiselela inkqubo kunye nokusebenza. Oku kunokufezekiswa ngokukhetha isixokelelwano esifanelekileyo nokwamkela umkhondo wesixhobo esisemgangathweni. Ukwenza lula inkqubo yokucubungula akukwazi nje ukuphucula ukusebenza kweprogram, kodwa nokunciphisa ukuba nokwenzeka kweempazamo zeprogram.

4. Ukusetyenziswa kwee-subroutines: Kwezinye iinkqubo eziphinde zasetyenziswa, ii-subroutines kufuneka zisetyenziselwe ukuprograma. Oku kunokunciphisa ubude beprogram kunye nokuphucula ukusebenza kakuhle kunye nokufundeka kweprogram. Ngexesha elifanayo, i-subroutine inokuguqulwa ngokulula kwaye igcinwe ukuphucula ukuguquguquka kunye nokuphinda kusetyenziswe inkqubo.

IV. Izinto ezilungileyo zeCNC Machining Centre

Iziko lomatshini le-CNCineenzuzo ezininzi ezibalulekileyo, ezenza ukuba isetyenziswe ngokubanzi kwishishini lemveliso yanamhlanje:

1. Nciphisa inani lezixhobo zokusebenza: Ngenxa yokuba isikhungo somatshini sinokufikelela kwimisebenzi eyahlukeneyo yomatshini ngokutshintsha isixhobo esizenzekelayo, ayifuni inani elikhulu lezixhobo eziyinkimbinkimbi xa kusetyenzwa iinxalenye ezinemilo enzima. Kuphela ngokuguqula inkqubo yokucubungula iinxalenye, ukuqhutyelwa kweengxenye zeemilo ezahlukeneyo kunye nobukhulu bunokufezekiswa, okunciphisa kakhulu ubuninzi kunye neendleko zezixhobo. Oku kunenzuzo kakhulu kuphuhliso kunye nokuguqulwa kweemveliso ezintsha, kwaye kunokusabela ngokukhawuleza kwiimfuno zemarike.

2. Umgangatho wokucutshungulwa okuzinzile: Iziko lomatshini lixhotyiswe ngenkqubo yokulawula ngokuchanekileyo kunye nobuchwepheshe obuphambili bokuqhuba, obunokuqinisekisa umgangatho ozinzileyo wokucubungula. Inokuchaneka okuphezulu kokusebenza kunye nokuphindaphinda, okunokuhlangabezana neemfuno zamashishini achanekileyo afana neenqwelomoya. Ukongezelela, inkqubo yokucubungula yeziko lokucubungula izinzile kwaye ingachaphazeleki kakhulu kwizinto zomntu, ezenza ukuba kuqinisekiswe ukuhambelana komgangatho wemveliso.

3. Ukusebenza okuphezulu kwemveliso: Kwimeko yobuninzi beentlobo ezahlukeneyo kunye nemveliso encinci, iIziko lomatshini le-CNCinokunika umdlalo opheleleyo kwiinzuzo zayo ezifanelekileyo. Ngokunciphisa ixesha lokulungiswa kwemveliso, ukulungiswa kwesixhobo somatshini kunye nokuhlolwa kwenkqubo, kunye nokusetyenziswa kweyona ndlela ilungileyo yokusika ukunciphisa ixesha lokusika, isikhungo somatshini sinokuphucula kakhulu ukusebenza kwemveliso. Kwangaxeshanye, isakhono sayo sokusebenza esiguquguqukayo sinokuhlangabezana neemfuno zobuqu zabathengi abahlukeneyo kwaye siphucule ukukhuphisana kwemarike kumashishini.

4. Imiphezulu entsonkothileyo enokusetyenzwa:amaziko Machining CNCiyakwazi ukucubungula imiphezulu entsonkothileyo ekunzima ukuyiqhuba ngeendlela eziqhelekileyo, njengemiphezulu egobileyo, imilo emilo eyodwa, njl. Oku kubonelela ngendawo yoyilo ebanzi kunye namathuba okuvelisa kwishishini lemveliso, kwaye kunceda ukukhuthaza ukuveliswa kwezinto ezintsha kunye nokuphuculwa kwemveliso.

V. Ukungalungi kwiZiko le-CNC Machining

Nangona iziko lomatshini le-CNC lineengenelo ezininzi, kukwakho nezinye iintsilelo ekufuneka ziqwalaselwe:

1. Iindleko zesixhobo somatshini ziyabiza: ixabiso lezixhobo zeamaziko Machining CNCiphezulu kakhulu, enokuba ngumthwalo omkhulu wotyalo-mali kwamanye amashishini amancinci naphakathi. Ukongeza, iindleko zayo zokugcinwa kunye nokugcinwa kwayo ziphezulu kakhulu, nto leyo efuna amagcisa aqeqeshiweyo ukuba asebenze kwaye alondoloze.

2. Ifuna abasebenzi bolondolozo ukuba babe nenqanaba eliphezulu: Ekubeni iziko lomatshini le-CNC liyi-high-tech.isixhobo somatshini we-CNC, ukulungiswa nokugcinwa kwayo kufuna ulwazi lobugcisa obuchwephesha kunye nezakhono. Abasebenzi bezolondolozo kufuneka baqhelane nesakhiwo, umgaqo kunye nenkqubo yokulawula isixhobo somatshini, kwaye bakwazi ukugweba ngokukhawuleza nangokuchanekileyo kunye nokusombulula iimpazamo. Kumashishini, kuyimfuneko ukuqeqesha okanye ukufumana abasebenzi abasemgangathweni ophezulu, oko kwandisa iindleko zomsebenzi weshishini.

VI. Ukusetyenziswa kweZiko loMatshini le-CNC

Iziko lomatshini le-CNC lisetyenziswa kakhulu kumashishini ahlukeneyo. Le ilandelayo yimimandla yesicelo eqhelekileyo:

1. Indawo ye-Aerospace: Kwibala le-aerospace, ukuchaneka kunye nomgangatho wamacandelo aphezulu kakhulu. IIziko lomatshini le-CNCinokusebenza iindawo ezahlukeneyo zeemilo ezintsonkothileyo, ezinje ngeencakuba zenjini yenqwelomoya, iinxalenye zesakhiwo sesiphekepheke, njl.njl., ukuhlangabezana neemfuno eziphezulu kwibala le-aerospace.

2. Ishishini lokwenziwa kweemoto: Ishishini lokwenziwa kweemoto yenye yeenkalo zezicelo ezibalulekileyo zamaziko omatshini e-CNC. Iziko lomatshini le-CNC lingasetyenziselwa ukucubungula iindawo eziphambili ezifana nebhloko ye-cylinder ye-injini yemoto, intloko ye-cylinder kunye ne-crankshaft, kunye neendawo ezinkulu ezifana nomzimba wemoto kunye ne-chassis. Ukukwazi kwayo ukusebenza ngokufanelekileyo kunye nokuchanekileyo kunokuphucula umgangatho kunye nokusebenza kakuhle kokwenziwa kweemoto.

3. Ishishini lemveliso yokungunda: Imveliso yokungunda yenye indawo ebalulekileyo yesiceloIziko lomatshini le-CNC. Ukuchaneka kunye nomgangatho wokubumba kuchaphazela ngokuthe ngqo umgangatho kunye nokusebenza kakuhle kwemveliso yemveliso. Iziko lomatshini le-CNC linokuqhuba iimilo ezahlukeneyo ezintsonkothileyo zokubumba, ezinje ngenaliti yokubumba, ukubumba okufayo, isitampu sokubumba, njl.

4. Ishishini le-elektroniki: Kwishishini le-elektroniki,amaziko Machining CNCingasetyenziselwa ukucubungula amacandelo e-elektroniki ahlukeneyo, njengeebhodi zesekethe eziprintiweyo, iigobolondo zeefowuni eziphathwayo, iigobolondo zekhompyutha, njl. njl. Ukuchaneka kwayo okuphezulu kunye nekhono lokucubungula ngesantya esiphezulu kunokuhlangabezana neemfuno zoshishino lwe-elektroniki ukuchaneka kunye nomgangatho wamacandelo.

5. Ushishino lwezixhobo zonyango: Ishishini lezixhobo zonyango nalo lineemfuno eziphezulu kakhulu zokuchaneka kunye nomgangatho wamalungu. Iziko lomatshini le-CNC linokwenza iindawo ezahlukeneyo zesixhobo sonyango, njengezixhobo zotyando, amaqokobhe esixhobo sezonyango, njl.

Sixhengxe. Uphuhliso lwexesha elizayo lweCNC Machining Centre

Ngenkqubela phambili eqhubekayo yesayensi kunye nobuchwepheshe kunye nophuhliso oluqhubekayo lweshishini lemveliso, amaziko omatshini e-CNC nawo aya kuzisa amathuba amatsha ophuhliso kunye nemingeni. Nazi ezinye iindlela zophuhliso kwixesha elizayo:

1. Ubukrelekrele: IkamvaIziko lomatshini le-CNCiya kuba krelekrele ngakumbi, ngokufunda ngokuzimeleyo, uhlengahlengiso oluhambelanayo kunye neminye imisebenzi. Ngokusetyenziswa kwetekhnoloji yobukrelekrele bokwenziwa, iziko lomatshini linokwandisa ngokuzenzekelayo iiparamitha zomatshini kunye nendlela yesixhobo ngokweempawu kunye neemfuno zokusetyenzwa kwendawo yokusebenza, kunye nokuphucula ukusebenza kakuhle kunye nomgangatho.

2. Isantya esiphezulu: Ngokuphuculwa okuqhubekayo kweemfuno zeshishini lokuvelisa ukusebenza kakuhle kwemveliso, uphuhliso olukhawulezayo lwamaziko omatshini e-CNC luya kuba yinto engenakuphepheka. Kwixesha elizayo, iziko lomatshini liya kuba nesantya esiphezulu se-spindle, isantya sokutya esikhawulezayo kunye nokukhawulezisa okukhulu ukufezekisa imisebenzi yomatshini esebenza ngakumbi.

3. Indibaniselwano: Ukuze kuhlangatyezwane neemfuno zeshishini lemveliso ukwenzela ukusetyenzwa kwemisebenzi emininzi, iIziko lomatshini le-CNCiya kuphuhlisa kwicala le-composite. Iziko lomatshini elizayo liya kudibanisa imisebenzi eyahlukeneyo yokucwangcisa, njengokujika, ukugaya, ukugaya, ukucofa, njl.

4. Uhlaza: Ngokukhuthazwa okuqhubekayo kolwazi lokusingqongileyo, uphuhliso lohlazaamaziko Machining CNCiya kuba yinto ebalulekileyo kwixesha elizayo. Iziko lokulungisa lexesha elizayo liza kusebenzisa ngakumbi ukonga umbane kunye nobuchwephesha obungenabungozi kokusingqongileyo kunye nezixhobo zokunciphisa ukusetyenziswa kwamandla kunye nongcoliseko lokusingqongileyo.

5. Uthungelwano: Ngophuhliso oluqhubekayo lwetekhnoloji yolwazi, uphuhliso lothungelwano lweamaziko Machining CNCiya kuba yinto ebalulekileyo kwixesha elizayo. Iziko lomatshini elizayo liya kukwazi ukudibanisa kunye nokusebenzisana nezinye izixhobo kunye neenkqubo ngenethiwekhi, ukuqonda ukubeka iliso kude, ukuxilongwa kwempazamo, ukuhanjiswa kweprogram kunye neminye imisebenzi, kunye nokuphucula ukusebenza kakuhle kunye nobukrelekrele bolawulo lwemveliso.

VIII. Ukuqukumbela

Njengenkqubela phambiliisixhobo somatshini we-CNC, Iziko lomatshini le-CNC lidlala indima ebalulekileyo kwimveliso yanamhlanje. Ineempawu ezizodwa kunye neengenelo, inokuqonda ukusebenza ngokufanelekileyo nangokuchanekileyo, kwaye ibonelele ngamacandelo akumgangatho ophezulu kunye neemveliso kumashishini ahlukeneyo. Ngenkqubela phambili eqhubekayo yenzululwazi nobuchwepheshe kunye nophuhliso oluqhubekayo lweshishini lemveliso, iziko lomatshini le-CNC liza kuqhubeka livelisa izinto ezintsha kunye nokuphucula, libonelela ngenkxaso yobugcisa eyomeleleyo kuphuhliso loshishino lwemveliso. Kwilixa elizayo,amaziko Machining CNCiya kuphuhlisa kwicala lobukrelekrele, isantya esiphezulu, ukudibanisa, uhlaza kunye nothungelwano, ukwenza igalelo elikhulu kwinguqu nophuculo kunye nomgangatho ophezulu wophuhliso loshishino lwemveliso.

Millingmachine@tajane.comLe yidilesi yam yemeyile. Ukuba uyayifuna, ungandithumelela i-imeyile. Ndilinde ileta yakho eseTshayina.